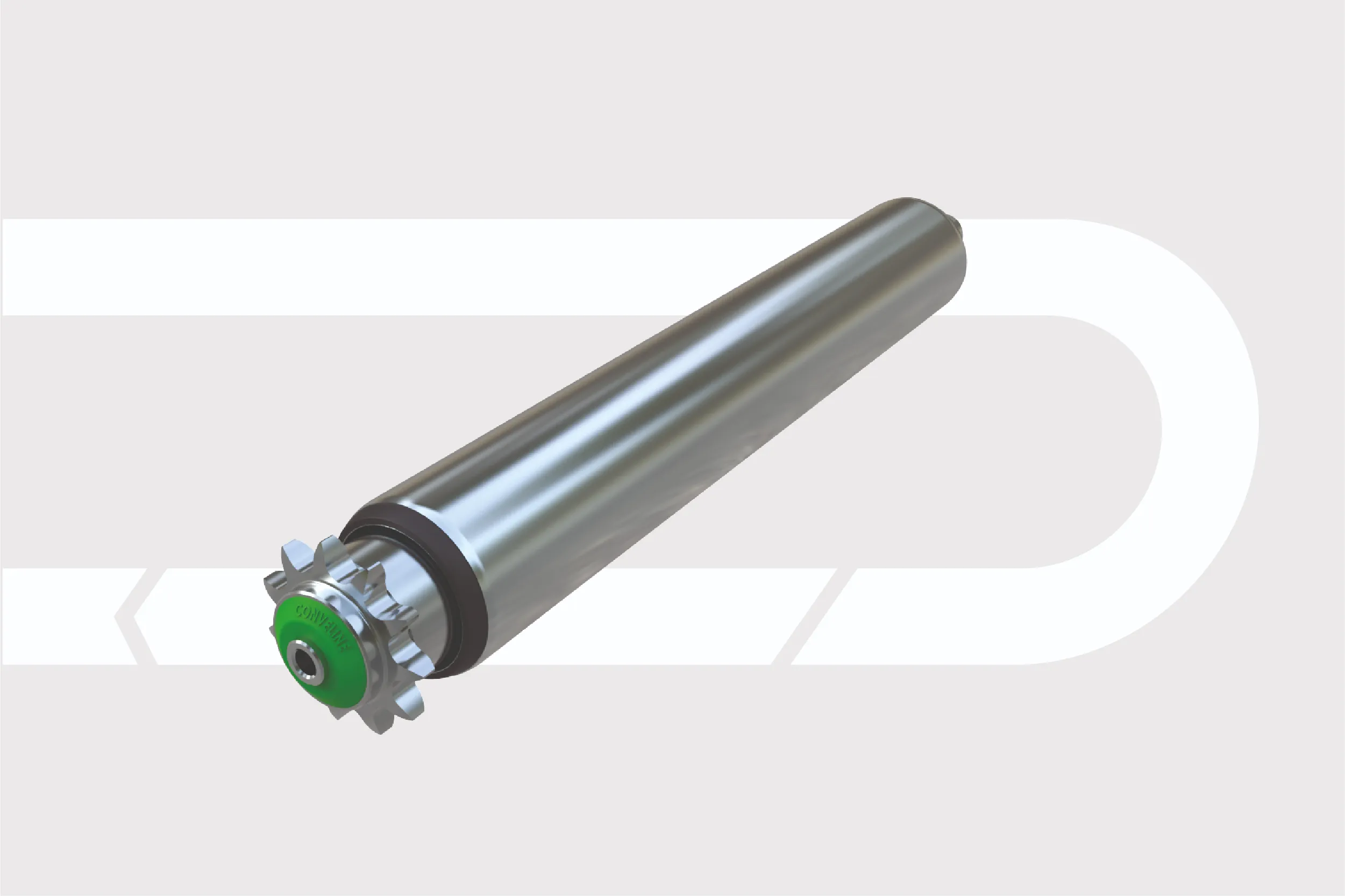

Conveyor Rollers for Automotive Industry

Conveline Rollers is one of India’s most reliable manufacturers and exporters of conveyor rollers for the automotive industry. With a strong focus on quality and performance, we specialize in designing and producing industrial rollers for automotive applications that meet modern manufacturing standards. Our conveyor solutions are built to handle the high demands of vehicle assembly lines, component movement, material transfer, and packaging areas in automotive facilities. In the fast-paced world of automobile production, conveyor rollers play a vital role in maintaining a smooth and efficient workflow.

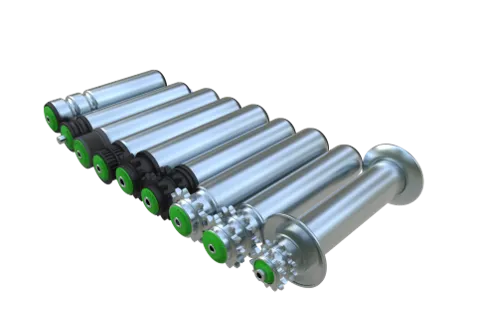

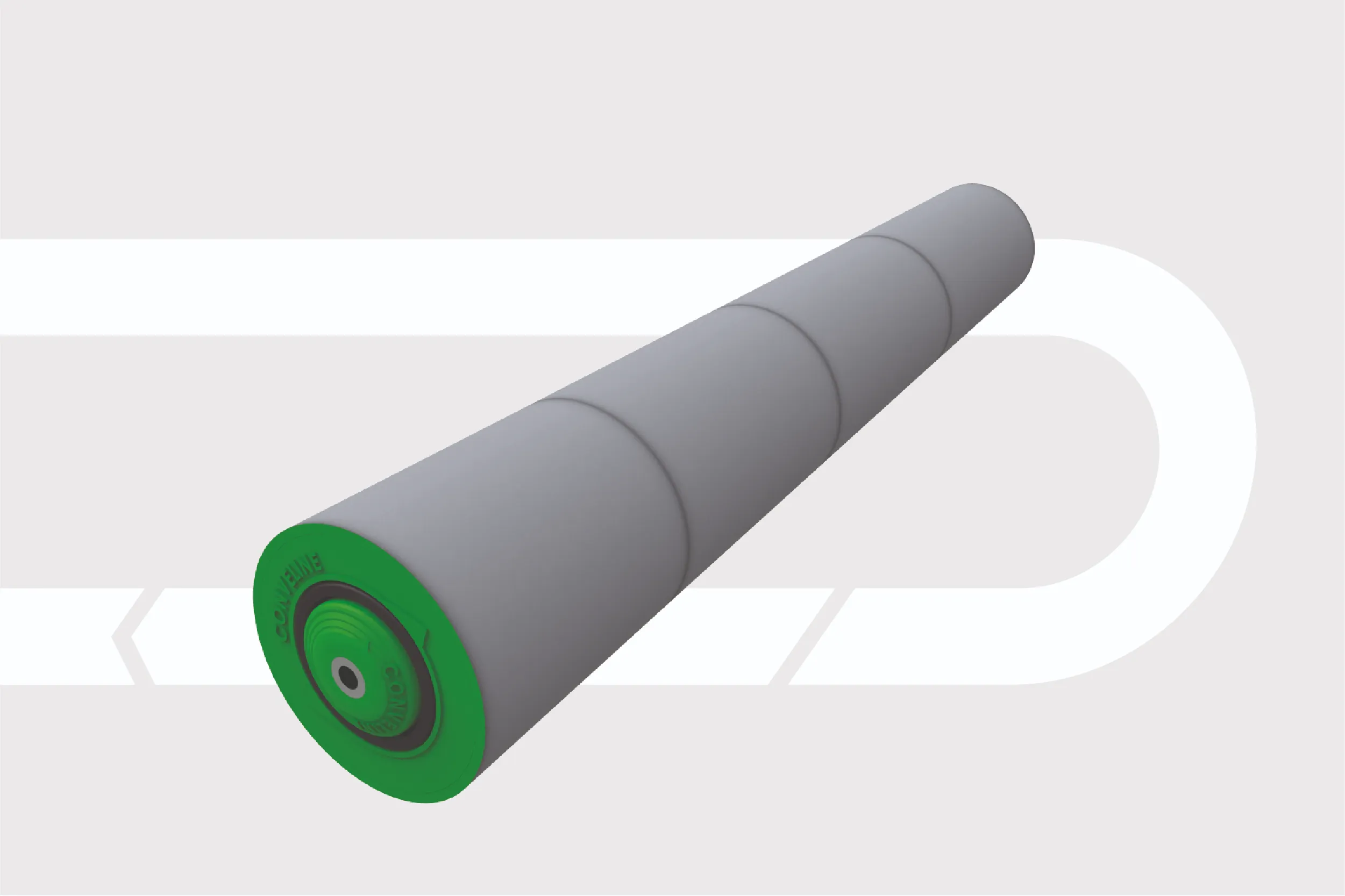

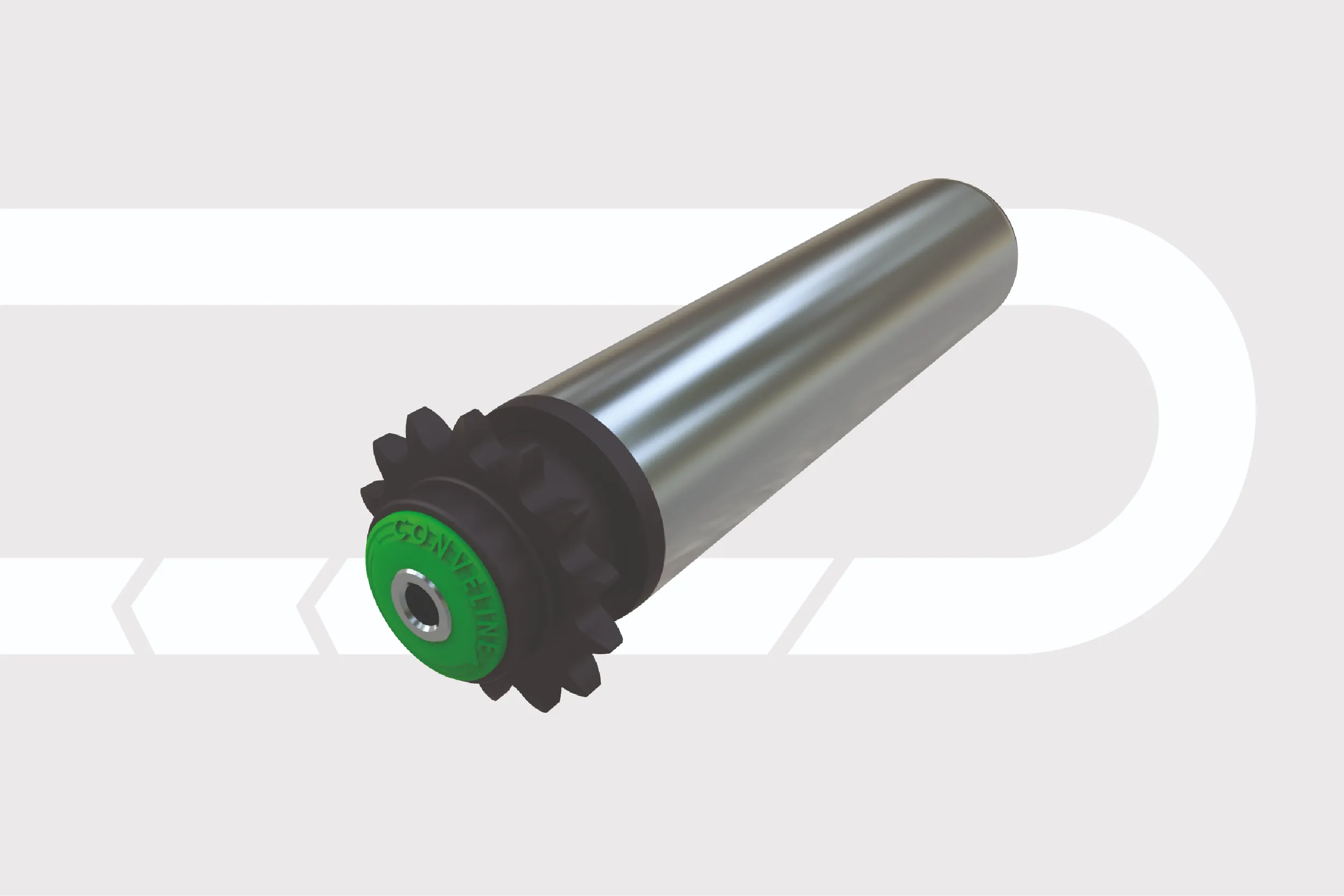

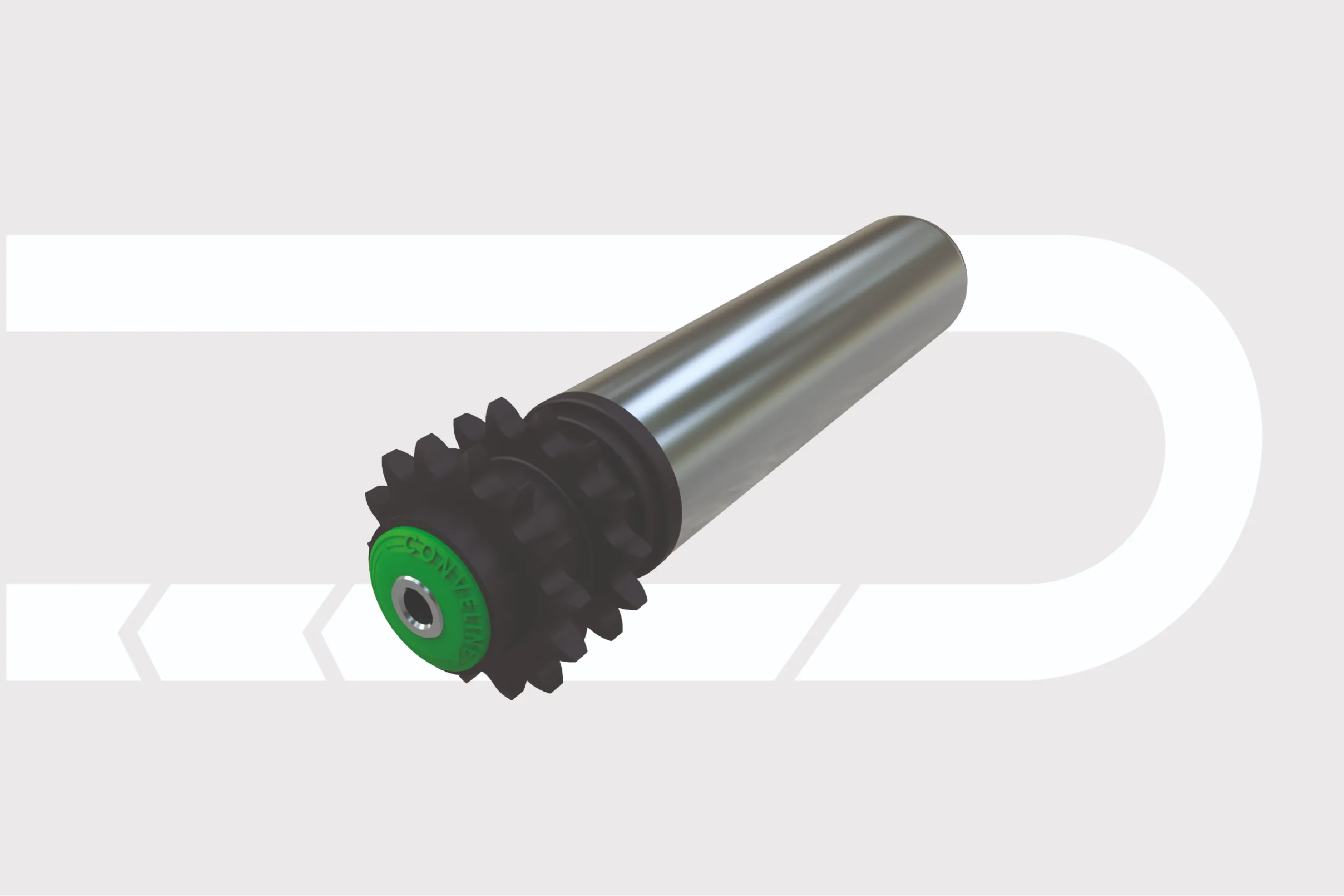

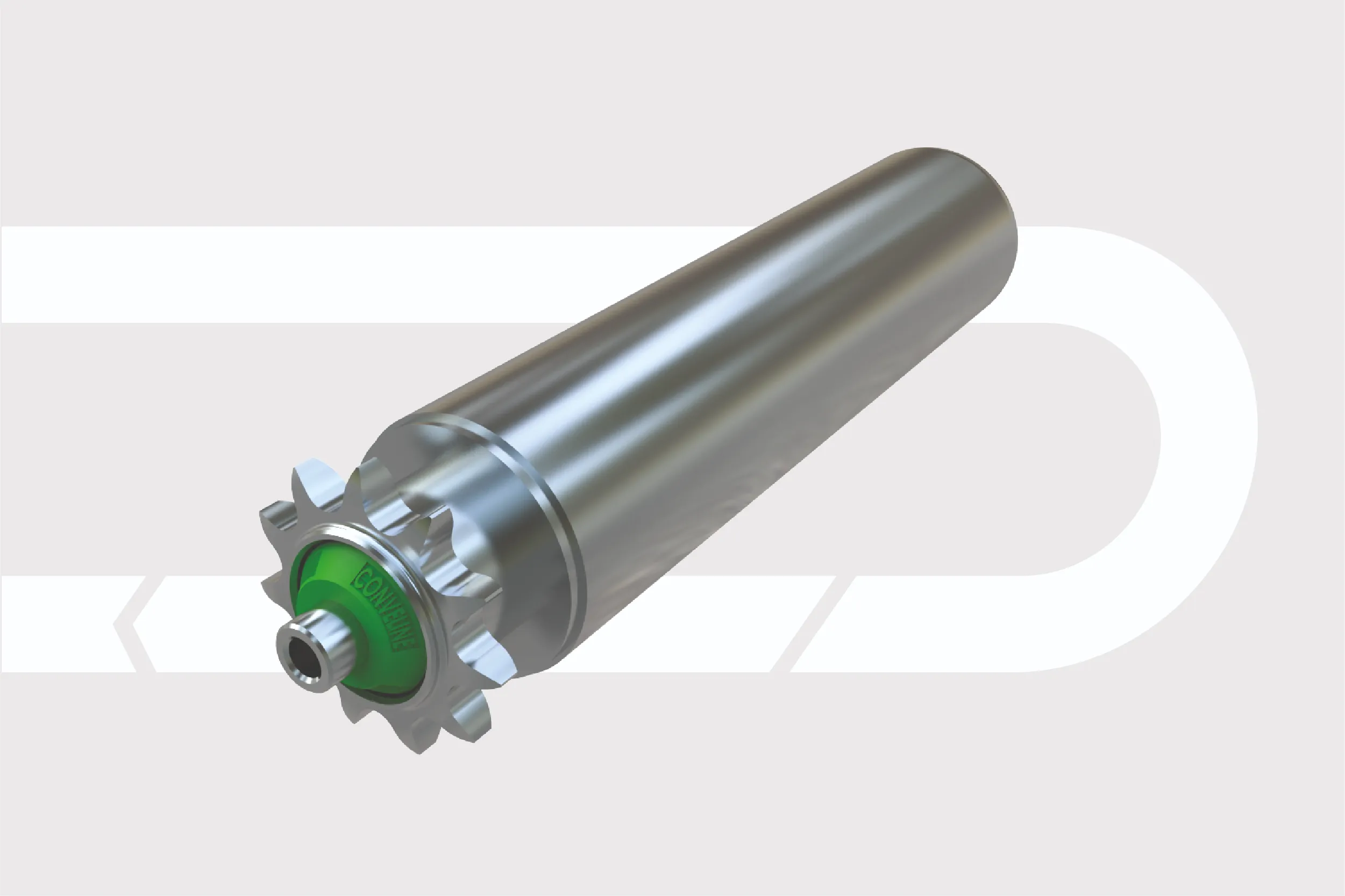

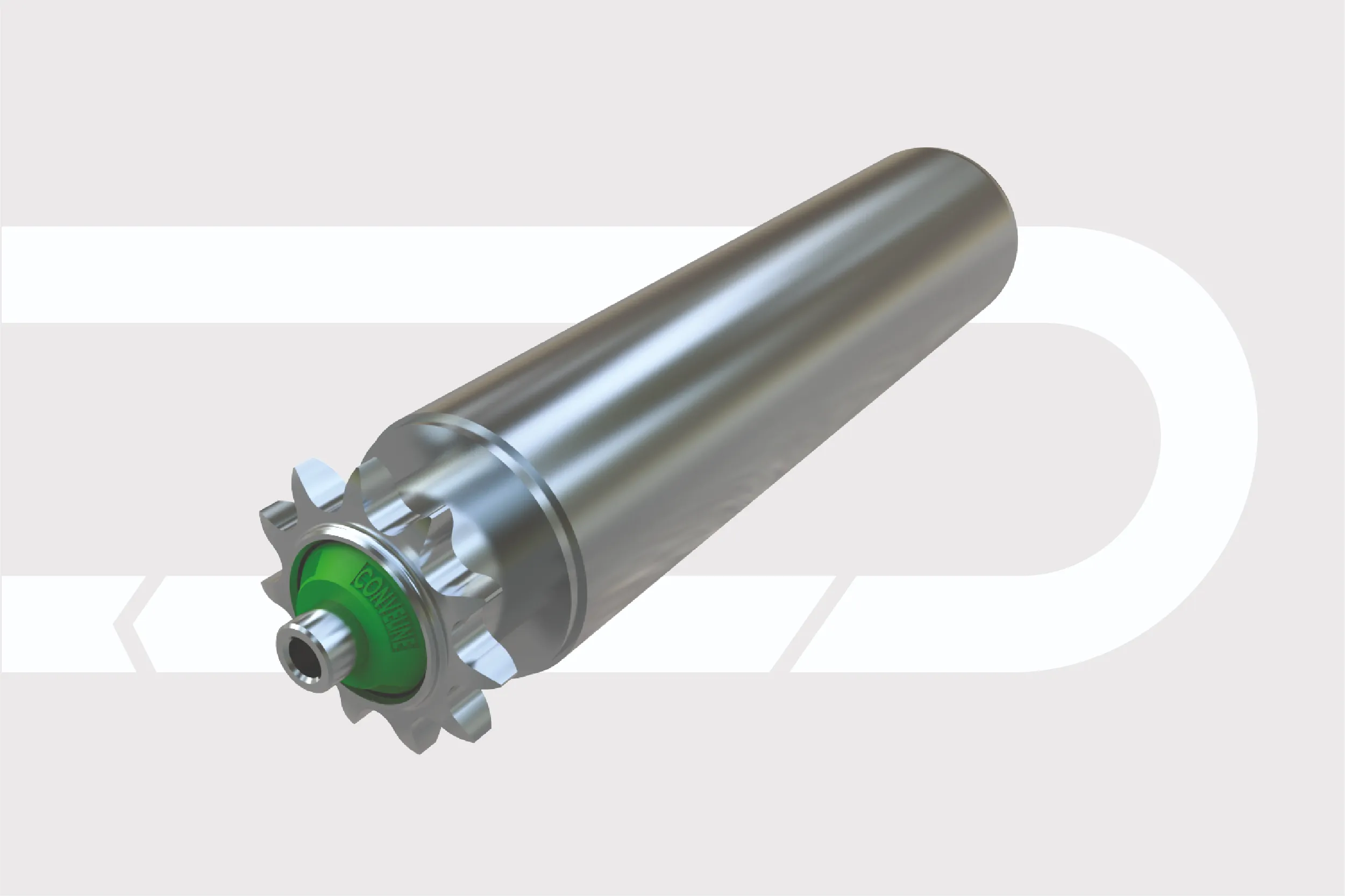

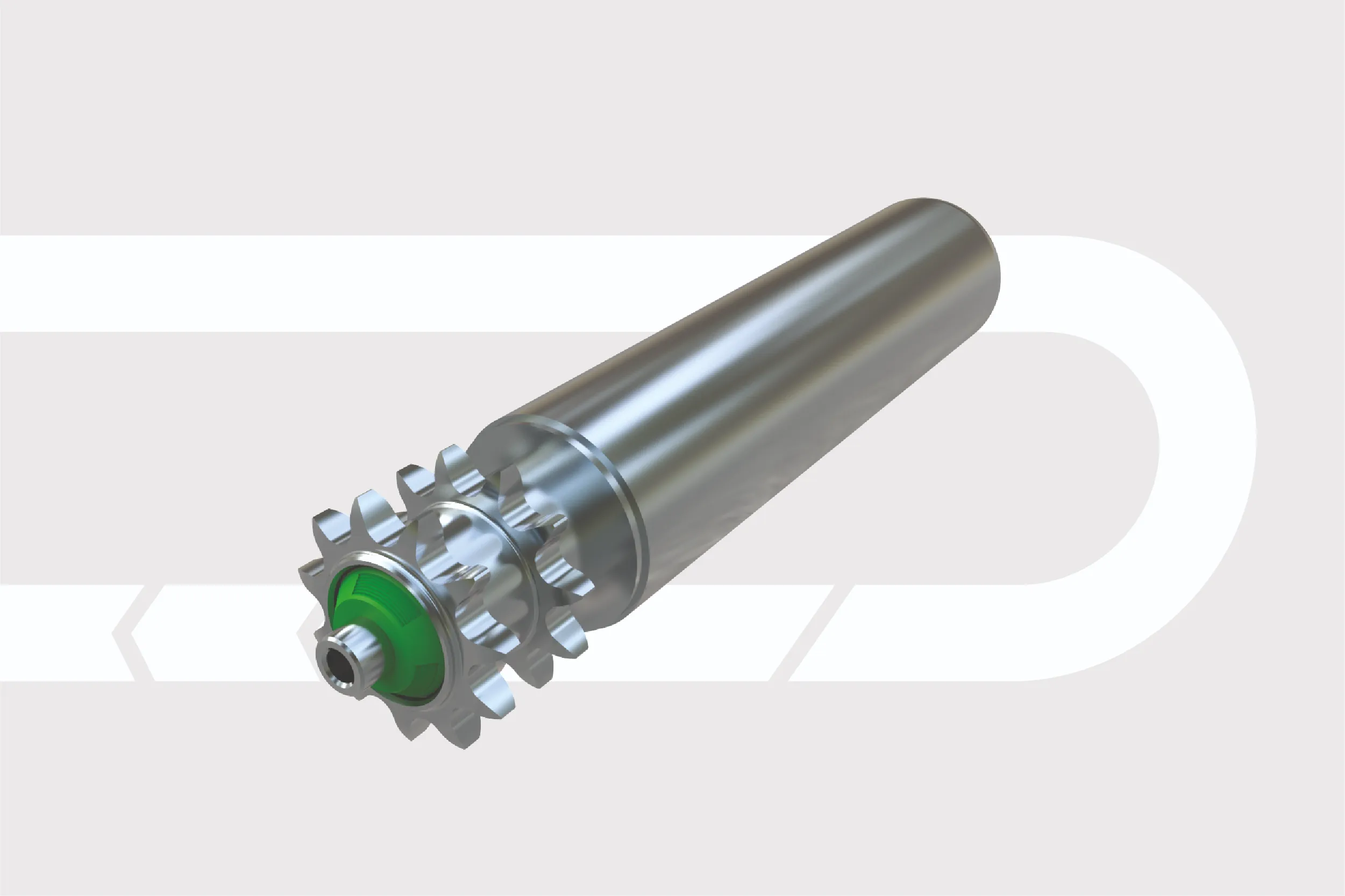

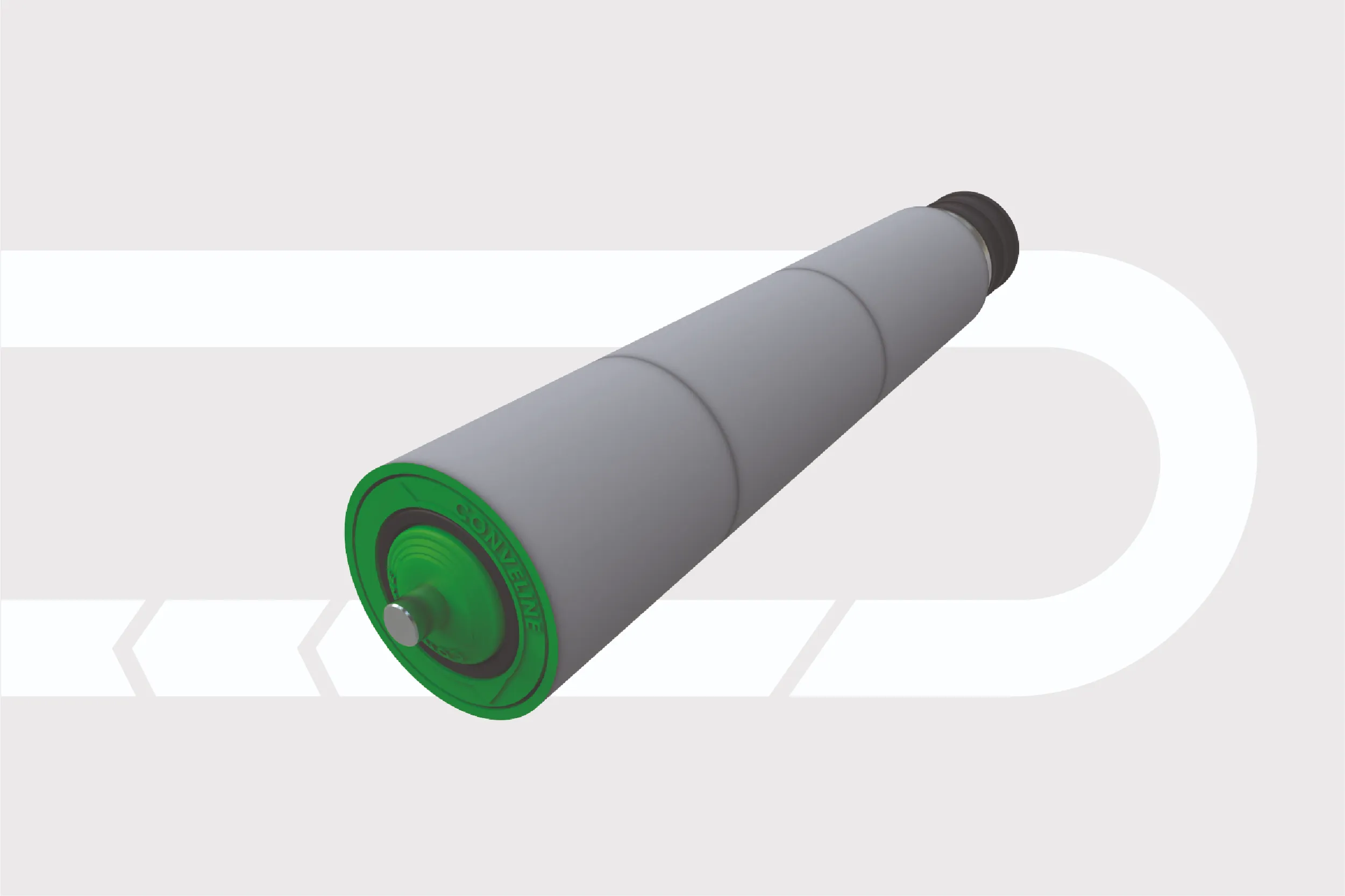

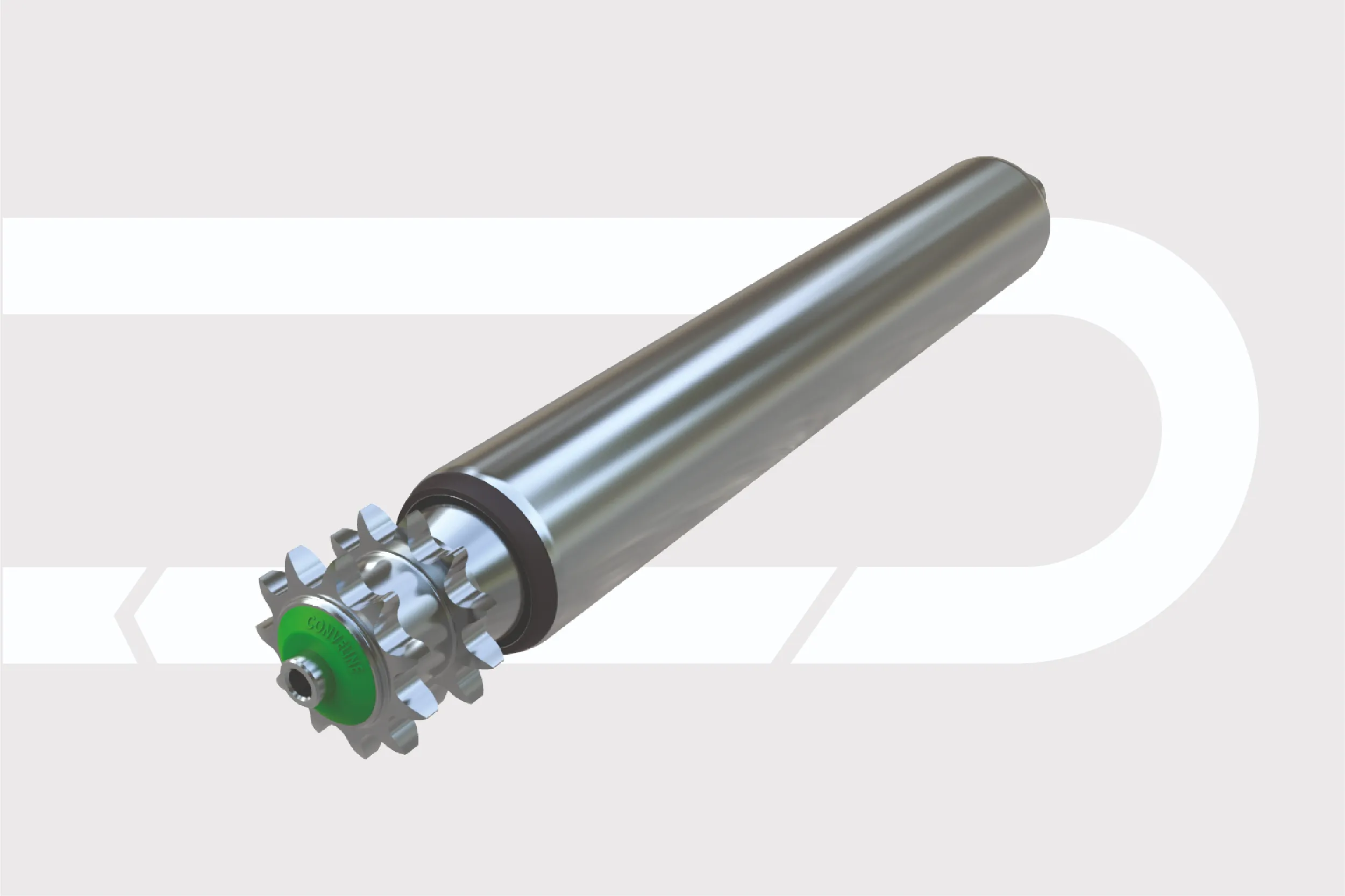

Conveline Rollers offers a wide range of rollers engineered for different stages of the automotive manufacturing process. These rollers are designed to move heavy auto parts like chassis, engines, bumpers, and tires across assembly stations with minimal manual effort and maximum safety.

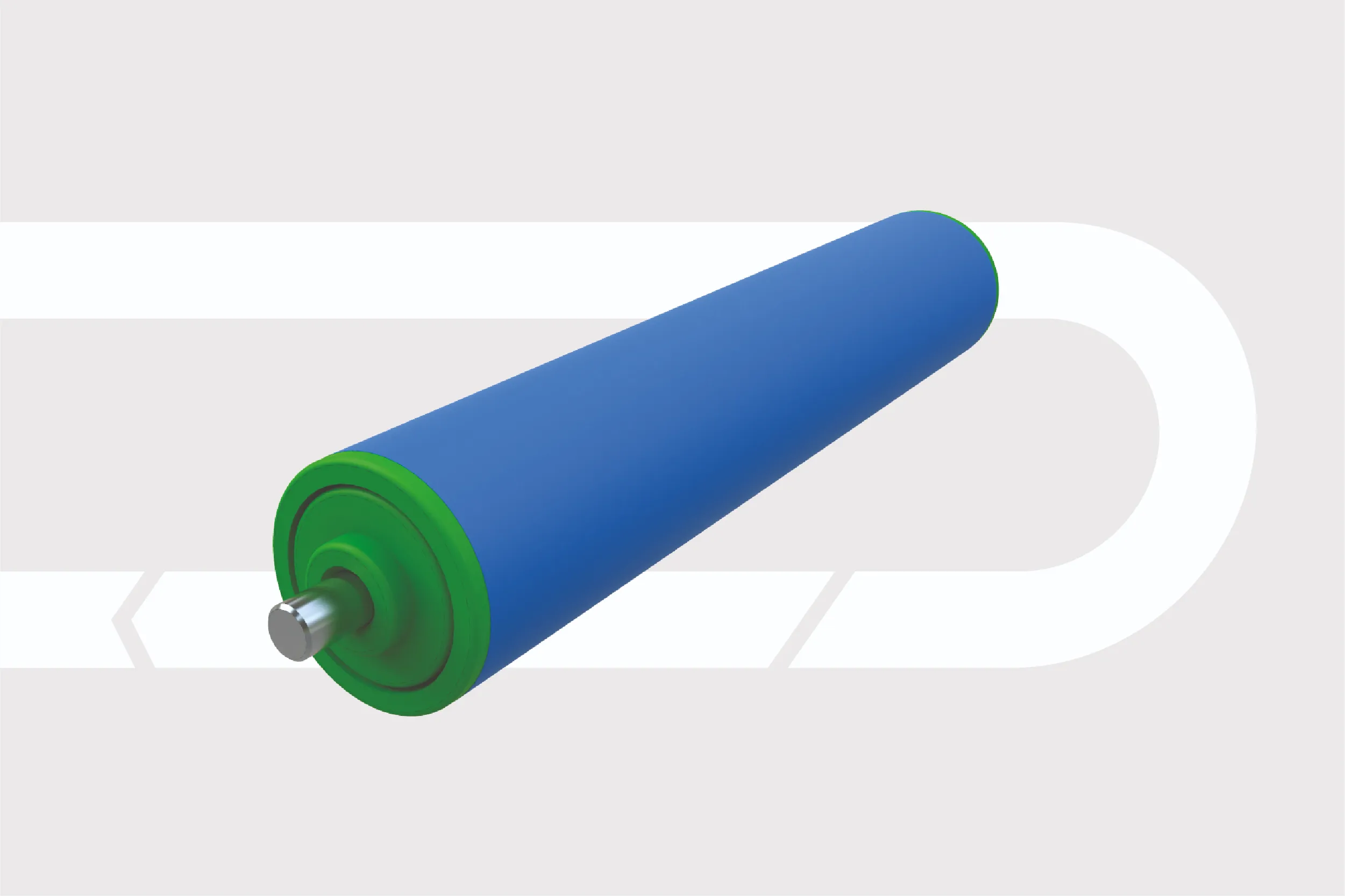

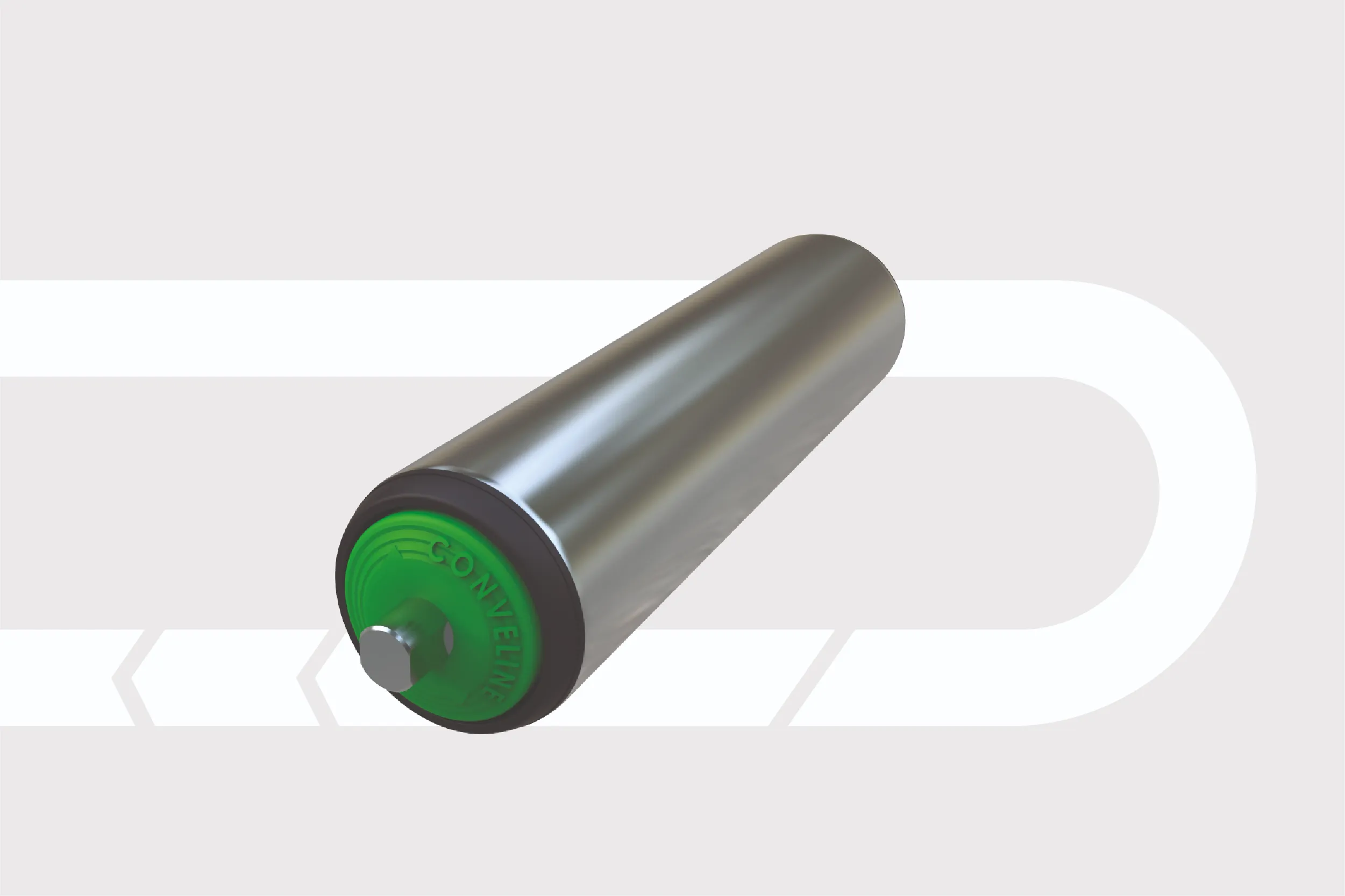

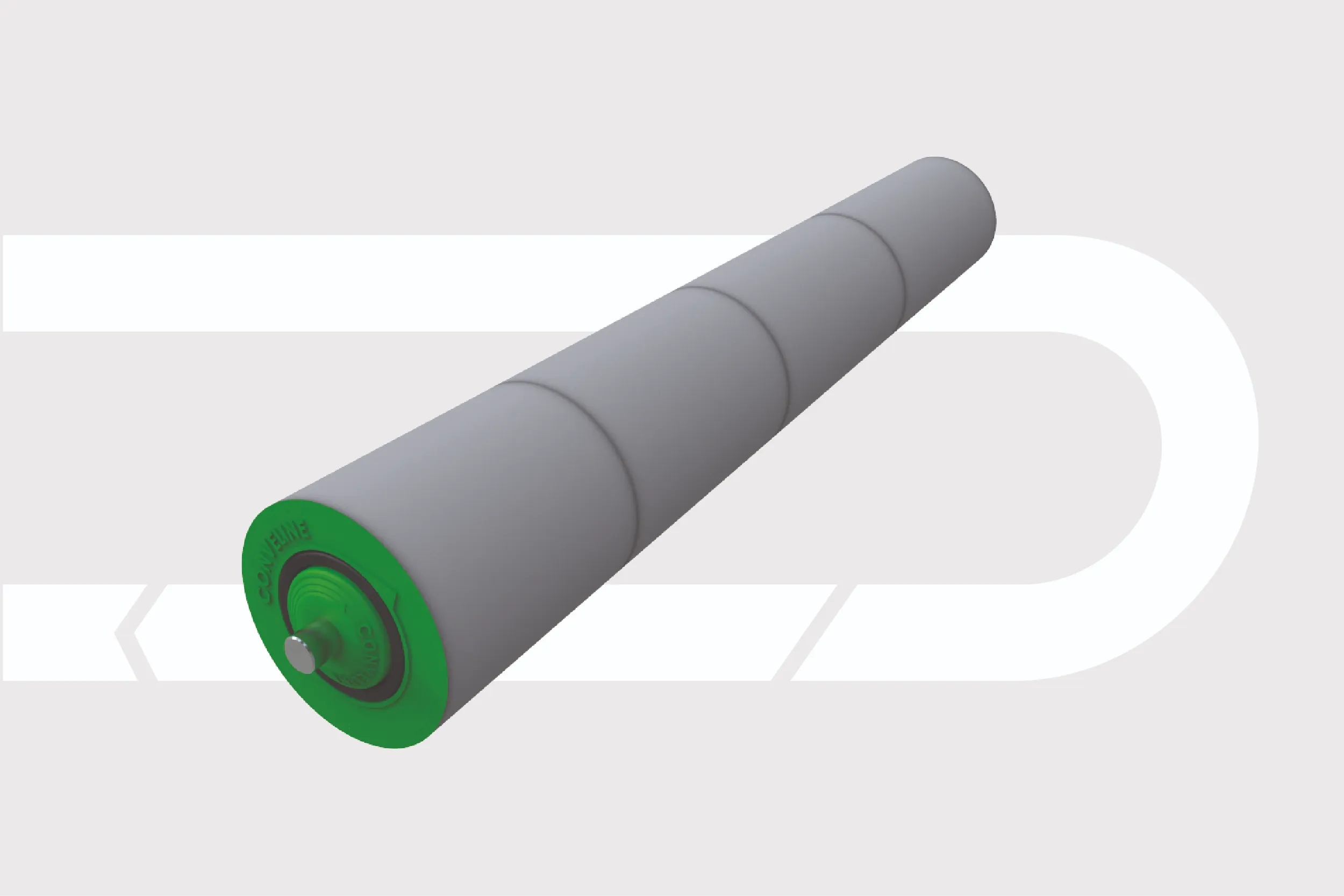

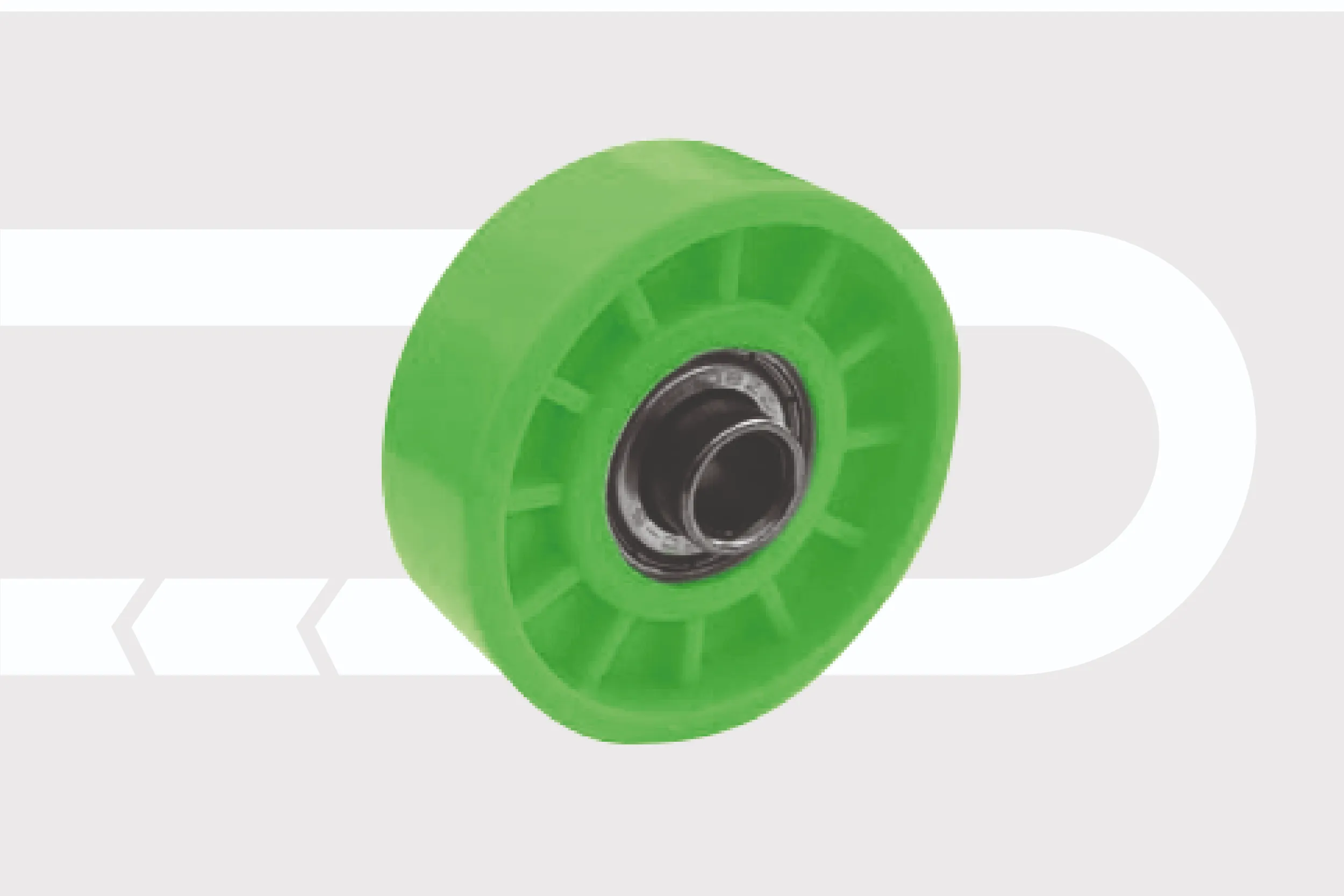

Our rollers are made using durable materials that can withstand high loads, resist corrosion, and endure continuous operations without wear and tear. We offer both standard and custom roller options to meet the specific size, speed, and weight requirements of automotive plants. Whether you're running a component manufacturing unit or a large vehicle assembly plant, our systems integrate seamlessly with robotic and manual handling setups.

Rollers For the Automotive Industry

Conveline's conveyor roller systems are widely used for transporting car body parts, doors, axles, and other mechanical components from one station to another without interruption. They reduce handling time, enhance workplace safety, and help manufacturers maintain consistent output in high-volume environments. With precision alignment and smooth rotation, our rollers ensure minimal noise and low maintenance, improving overall plant efficiency.

As the automotive industry continues to evolve with smart manufacturing and automation, Conveline Rollers supports the transformation with innovative conveyor solutions. Our rollers for the automotive industry are compatible with both powered and gravity conveyor systems, allowing flexibility in usage across various production zones such as paint shops, body shops, and final assembly lines. When it comes to trusted conveyor rollers for automotive industry, Conveline Rollers delivers value through quality, customization, and durability—helping you streamline operations and meet production targets with ease.

Compelete Effortless Solution

The automotive industry thrives on precision, speed, and efficiency. Behind the scenes, conveyor rollers play a crucial role in powering the smooth operation of automotive manufacturing and supply chain processes. Let's explore the remarkable ways conveyor rollers are utilized in the automotive industry, with a breakdown of their key functions and benefits.

- Production Line Assembly

Conveyor rollers transport various automotive components, such as engine parts, chassis, and electrical systems, along the assembly line. This ensures a seamless flow of parts, optimizing production processes and reducing manual handling.

- Quality Control and Testing

Conveyor rollers facilitate the movement of vehicles or components through inspection stations, where quality control checks and testing are conducted. This enables systematic and efficient evaluation of automotive products, ensuring adherence to rigorous industry standards.

- Warehouse and Distribution

Conveyor rollers streamline material handling within automotive warehouses, efficiently moving products from receiving areas to designated storage locations. They optimize space utilization, improve inventory management, and facilitate smooth distribution.

Benefits of Conveyor Rollers

So, why are conveyor rollers so important in the courier industry? Here are just a few of the benefits that they provide:

- Enhanced Efficiency: Conveyor rollers automate material handling processes, minimizing manual labor, reducing production bottlenecks, and increasing overall operational efficiency in the automotive industry.

- Improved Accuracy and Quality: With automated sorting, tracking, and inspection capabilities, conveyor rollers ensure accurate assembly and stringent quality control, resulting in superior automotive products.

- Cost Savings: By optimizing production processes, minimizing manual labor, and reducing errors, conveyor rollers contribute to cost savings in the automotive industry, boosting profitability.

- Workplace Safety: Conveyor rollers reduce the need for manual lifting and carrying of heavy automotive components, promoting a safer work environment and reducing the risk of injuries.