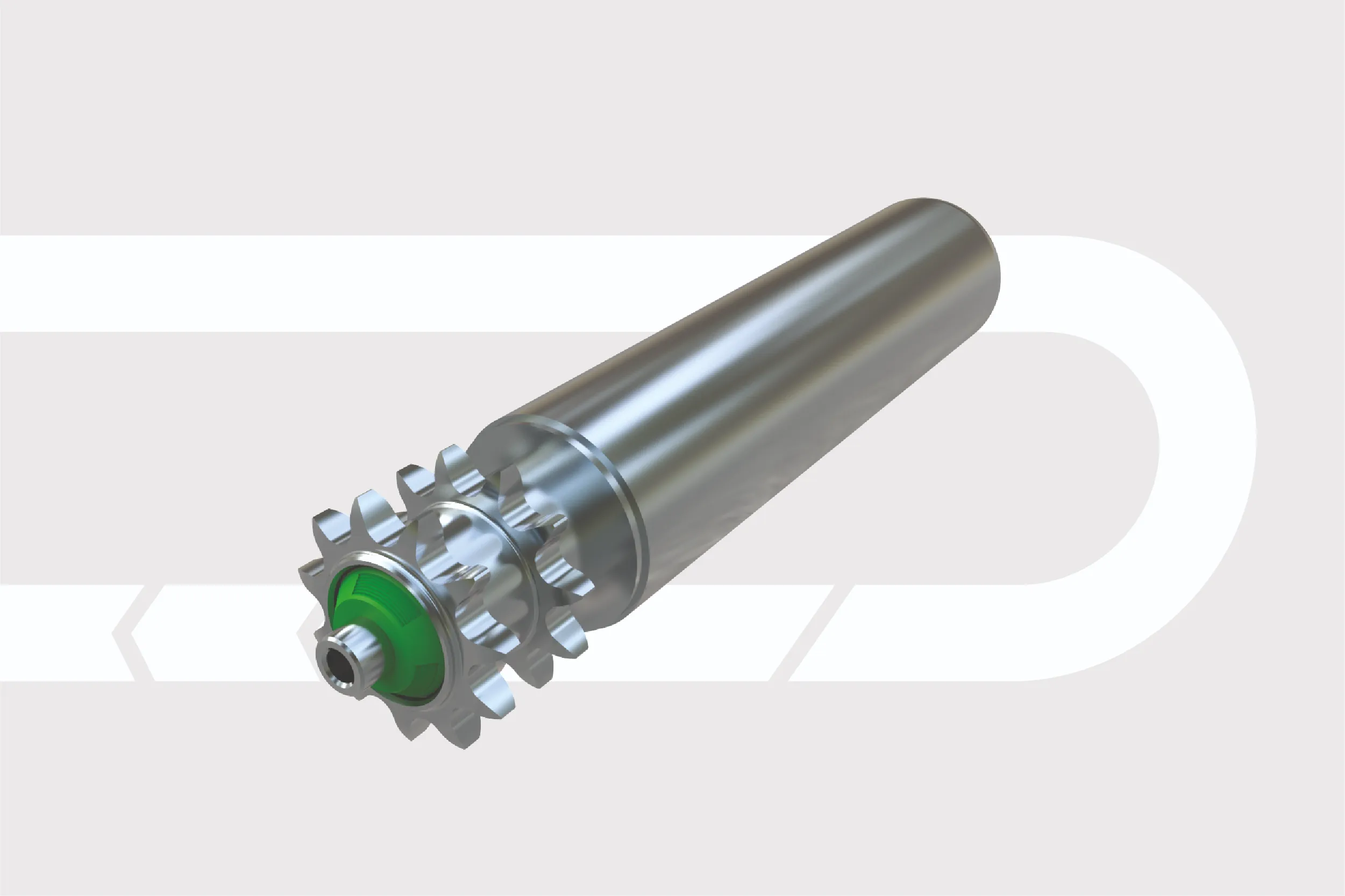

Pharmaceutical Roller Conveyor

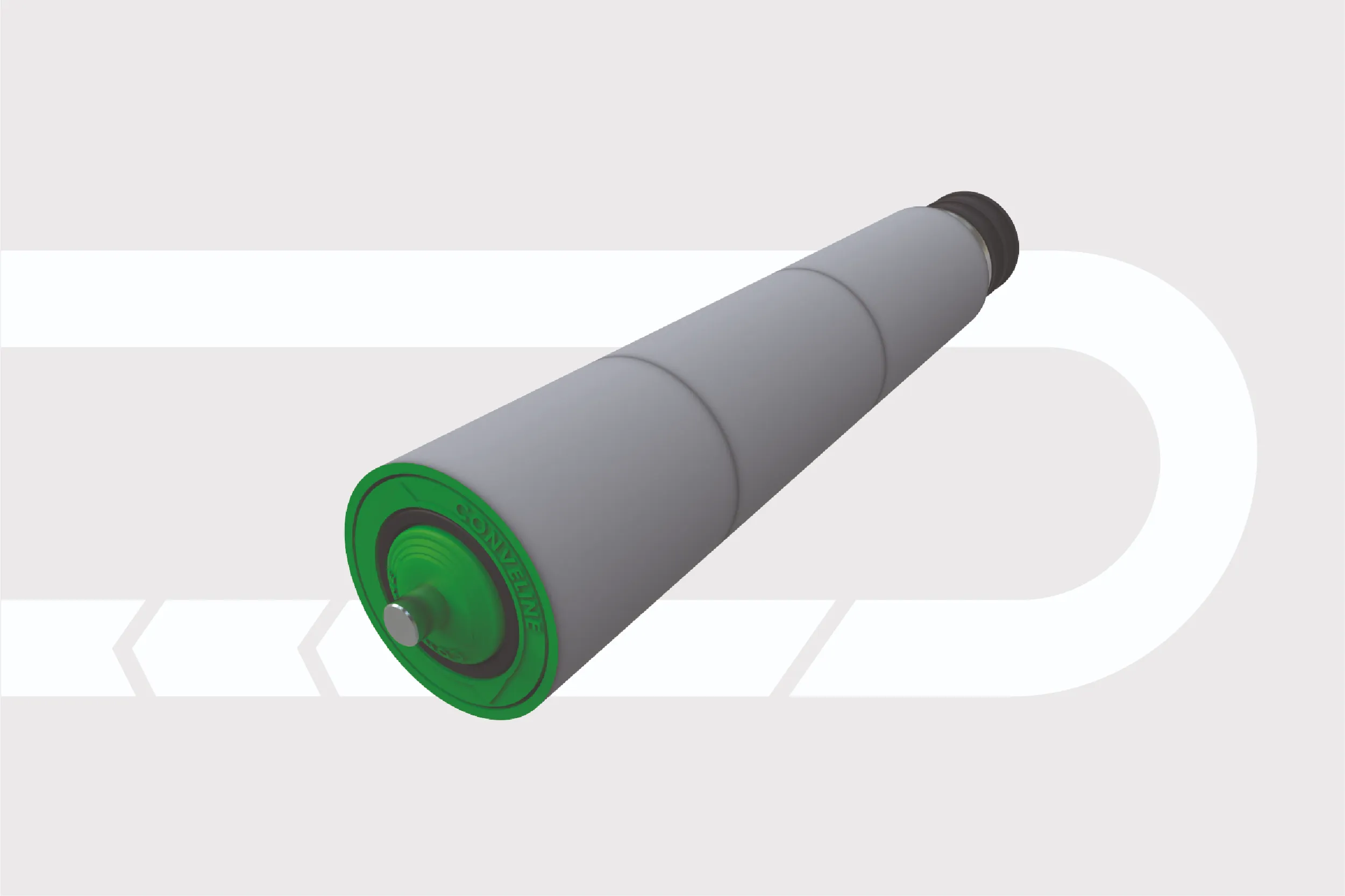

Conveline Rollers is a well-known name in India for manufacturing high-quality roller conveyors for the pharmaceutical industry. With years of expertise and advanced engineering, we design conveyor systems that are ideal for pharmaceutical manufacturing, packaging, and inspection areas. Our conveyors are built with precision and hygiene in mind, meeting the demanding requirements of pharmaceutical companies, nutraceutical producers, and healthcare packaging units. Understanding the strict hygiene, safety, and regulatory needs of the pharmaceutical industry, we offer conveyor solutions that support sterile operations and contamination-free transport of sensitive products. From tablets and capsules to vials, syringes, and blister packs, our pharmaceutical industry conveyor systems ensure safe and reliable product movement across production lines.

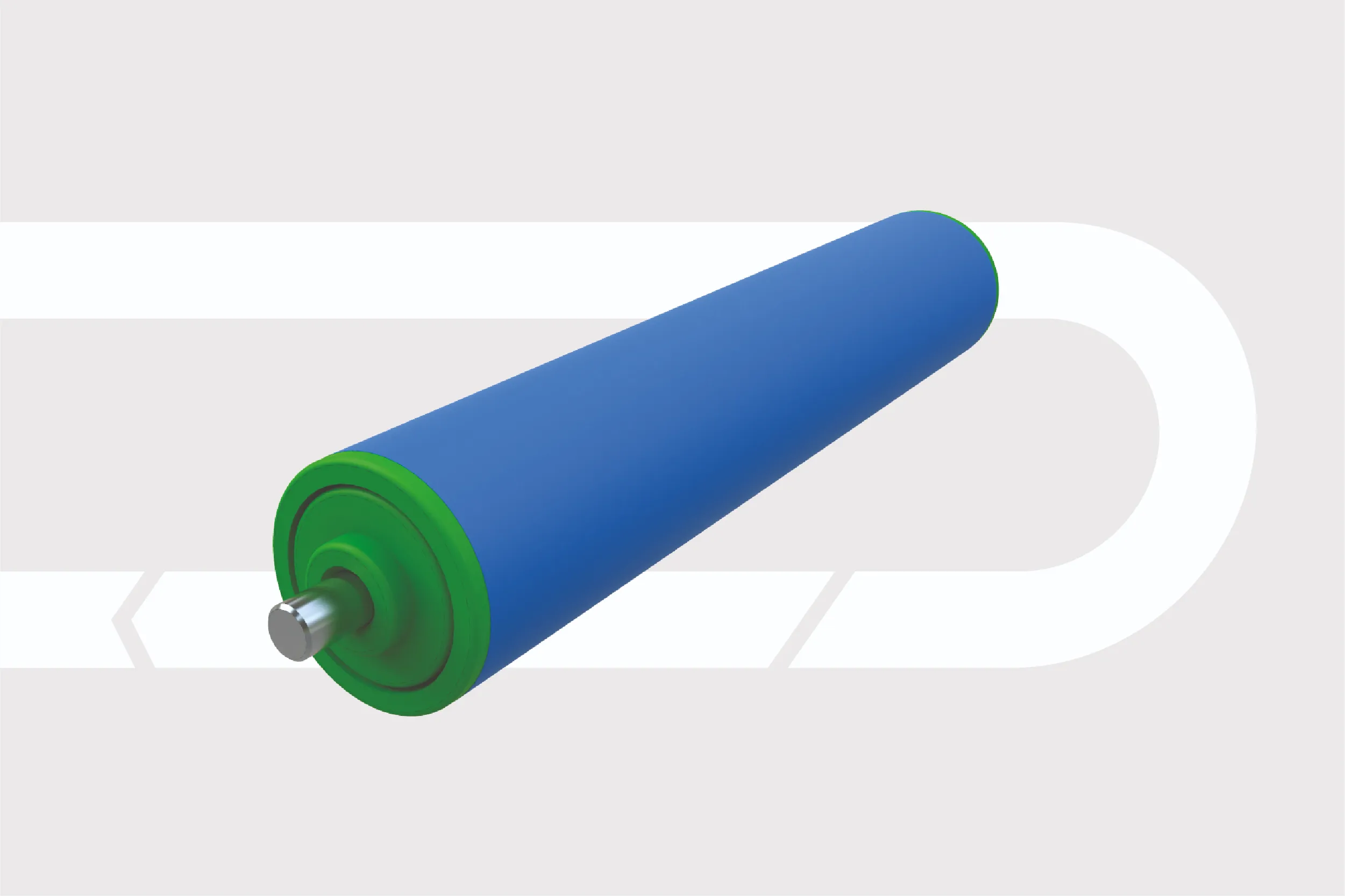

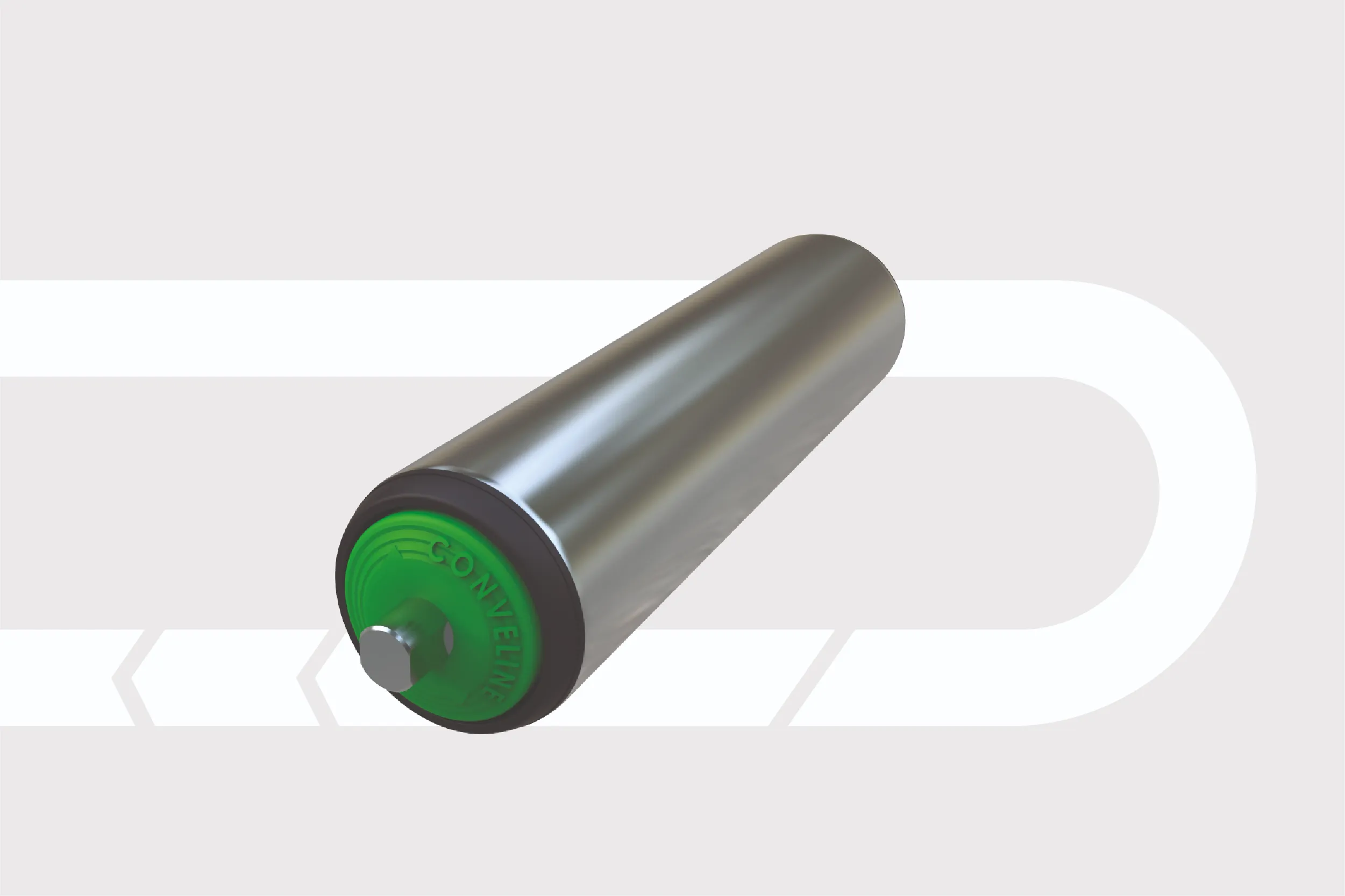

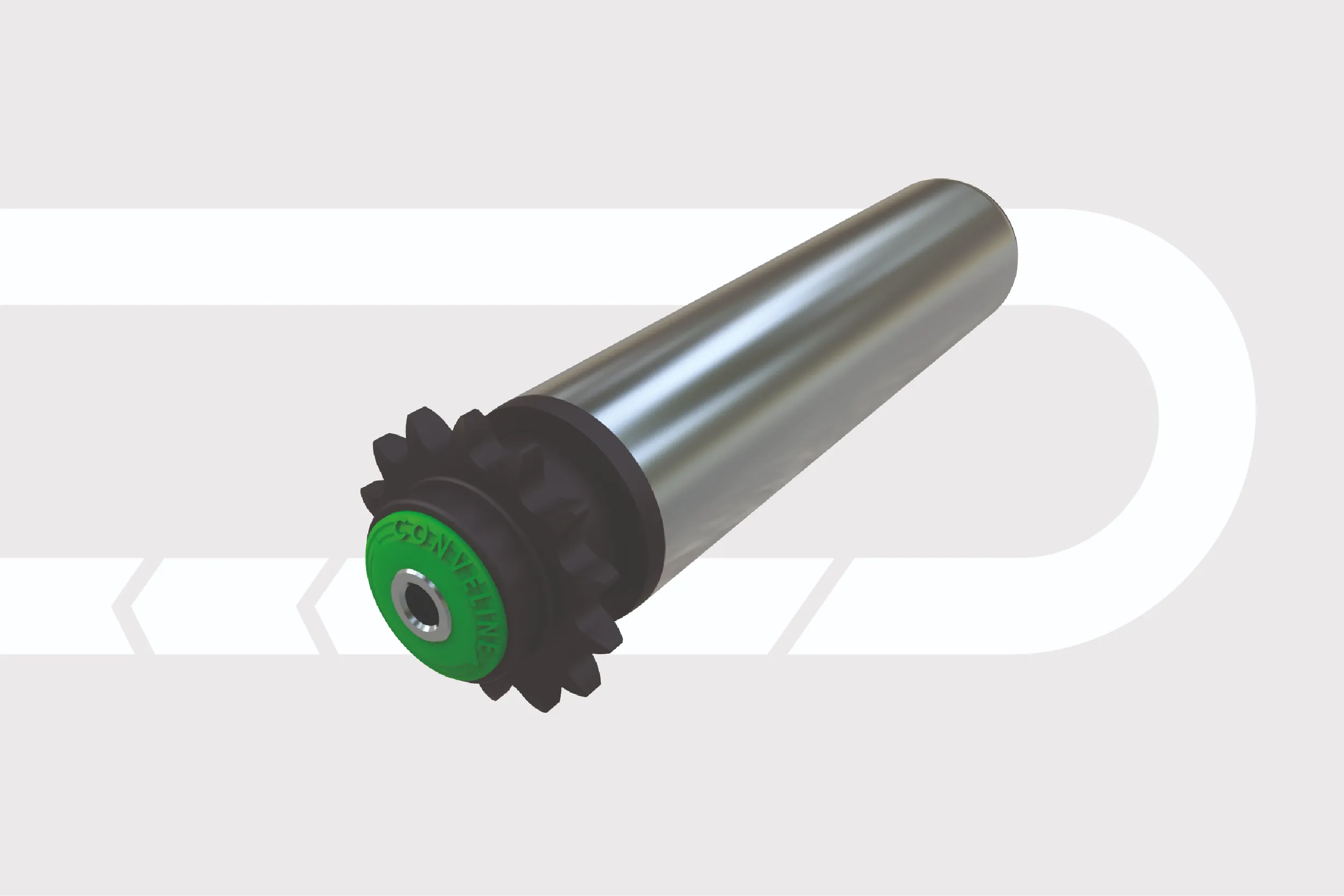

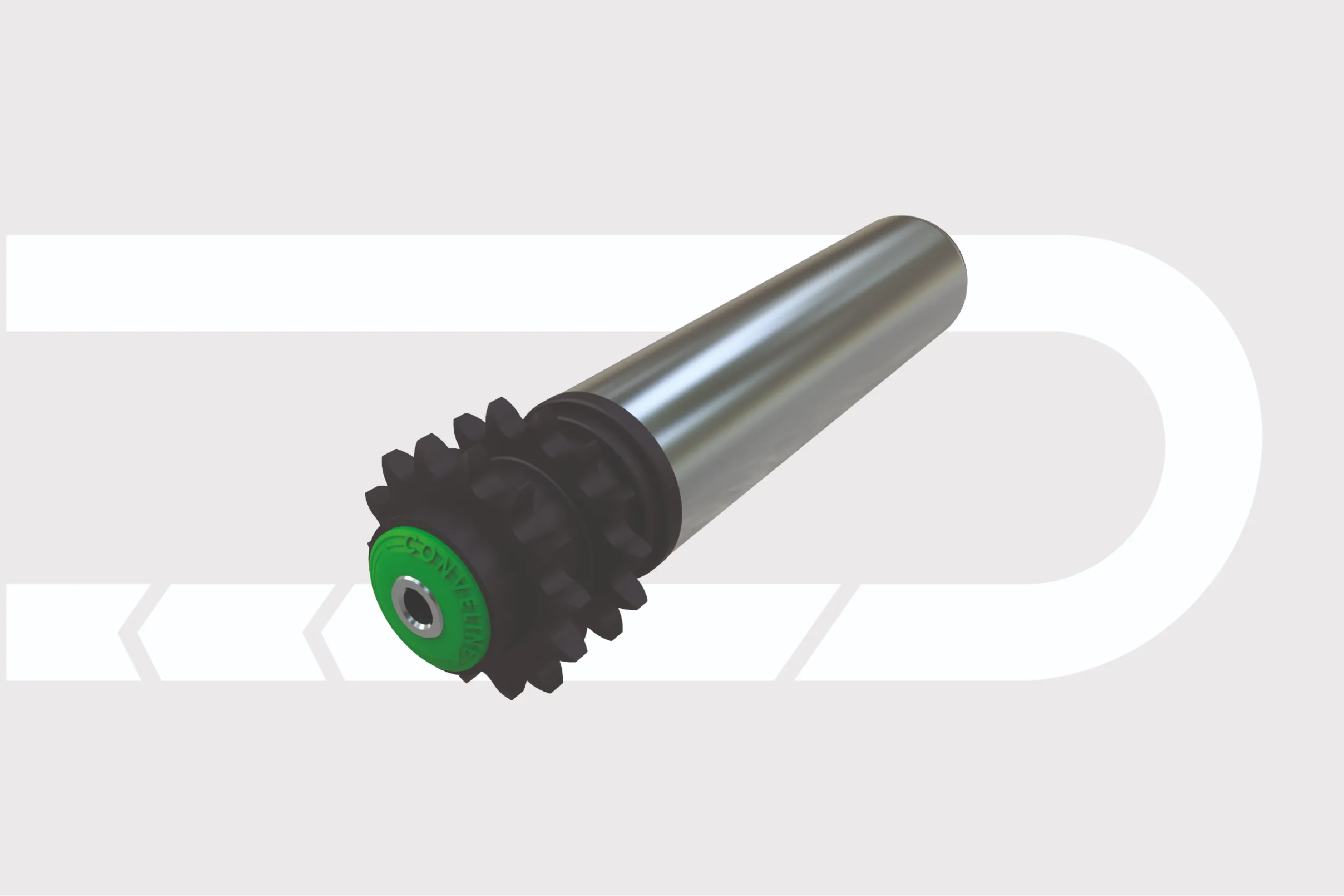

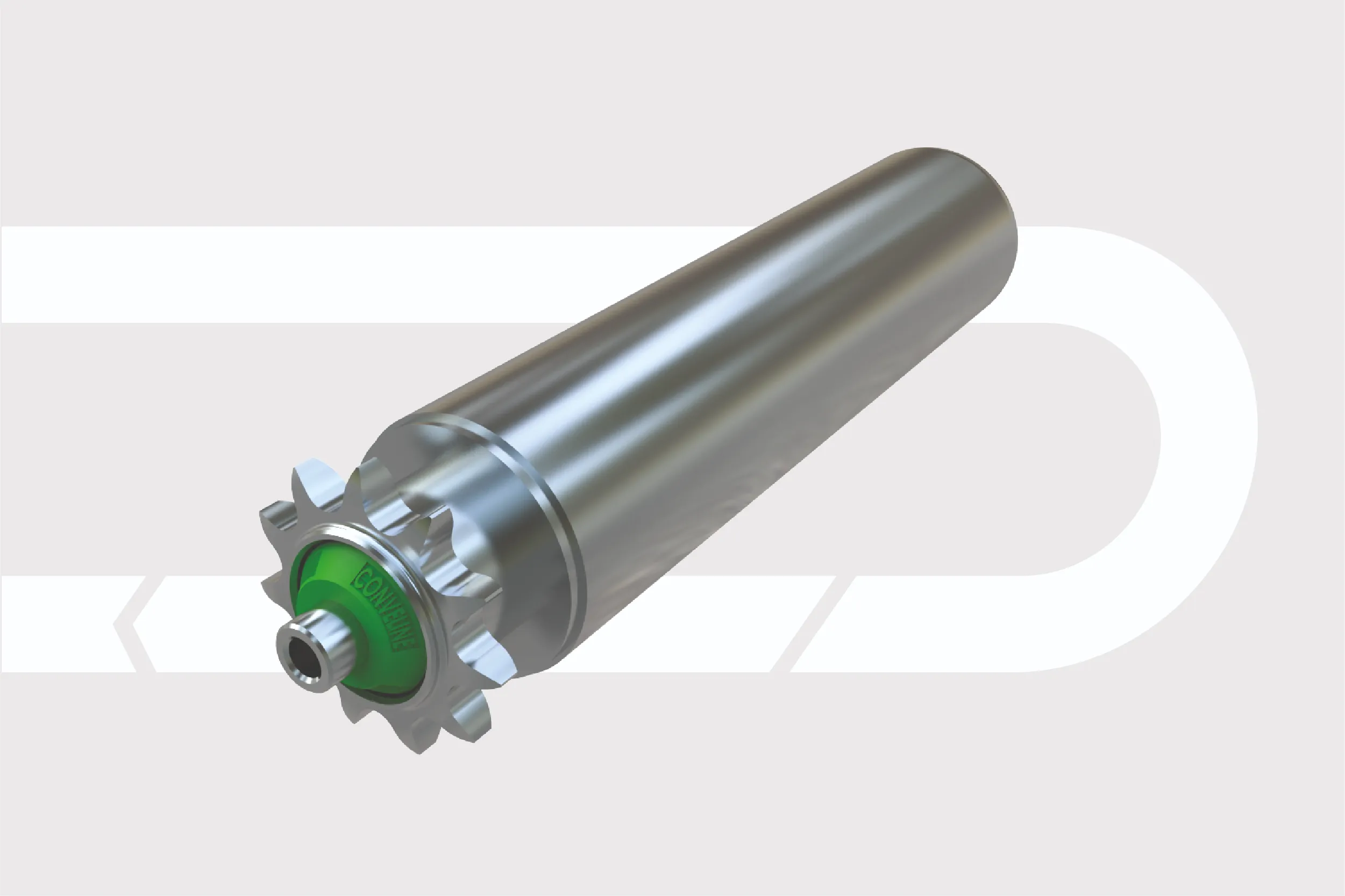

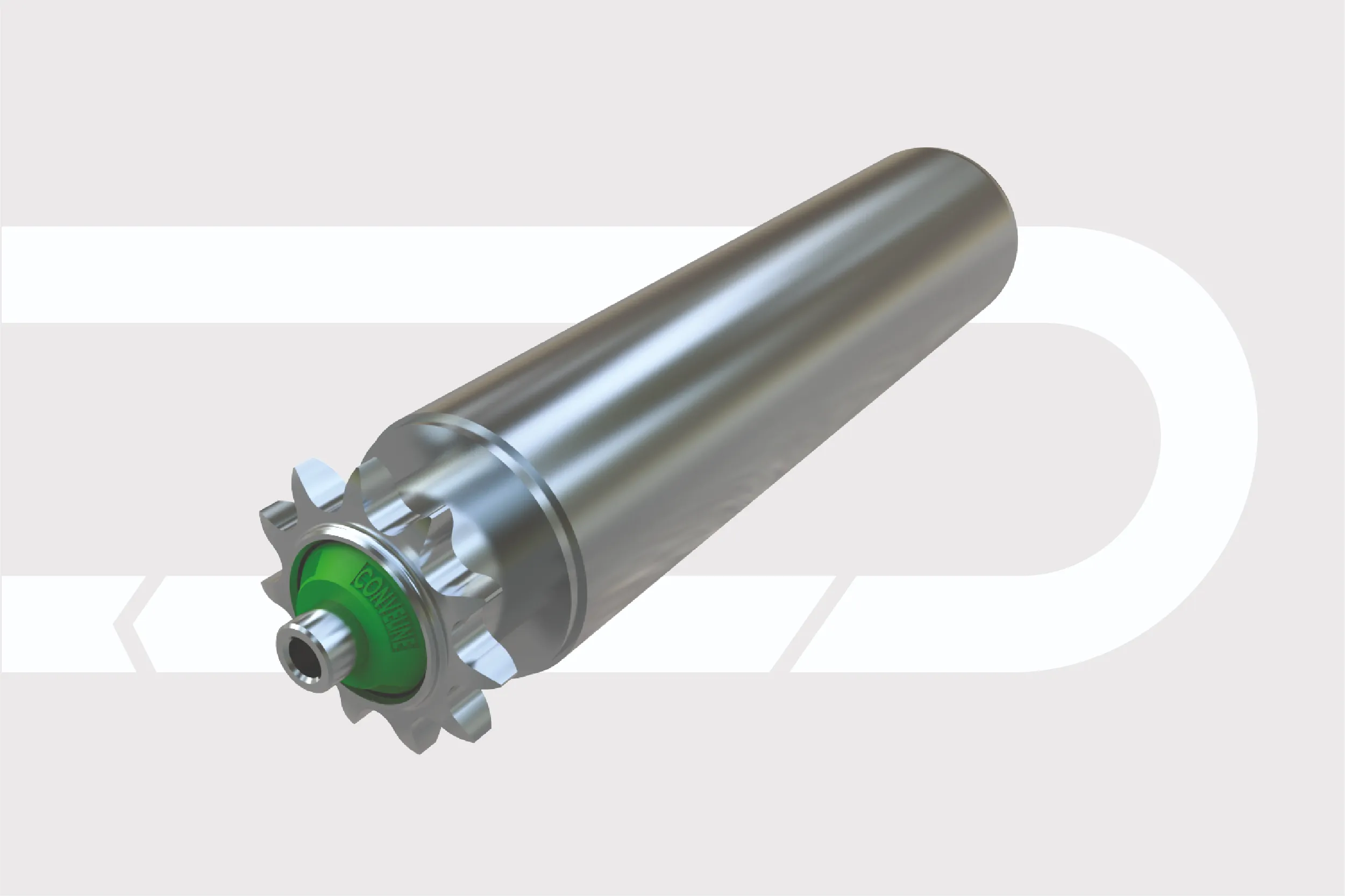

All our pharmaceutical conveyors are made using high-grade stainless steel and FDA-approved materials to prevent rust, corrosion, or bacterial growth. The rollers, belts, and supporting frames are easy to clean and designed for smooth operation in sterile environments. Whether your facility requires linear movement, accumulation, or complex transfers, our modular designs can be adapted to fit the available space and function.

Pharmaceutical Roller Conveyor Manufacturer

As a leading pharmaceutical roller conveyor manufacturer, Conveline Rollers ensures every system is thoroughly tested to meet the highest industry standards. We provide tailored solutions for cleanrooms, inspection zones, filling lines, and end-of-line packing areas. We also offer chain conveyors, belt conveyors, and modular systems that seamlessly integrate with your existing setup.

Whether you're automating a single process or setting up an entirely new facility, our pharmaceutical industry conveyor systems can handle bulk production without compromising safety, hygiene, or accuracy. With Conveline Rollers, you get dependable, easy-to-maintain conveyor solutions that help you maintain regulatory compliance and optimize your pharmaceutical operations. Our industrial pharmaceutical conveyors are not only efficient but also contribute to minimizing human contact, which is essential for maintaining product integrity and quality. These systems reduce the chances of errors during packaging and labeling while improving the speed and consistency of output.

Compelete Effortless Solution

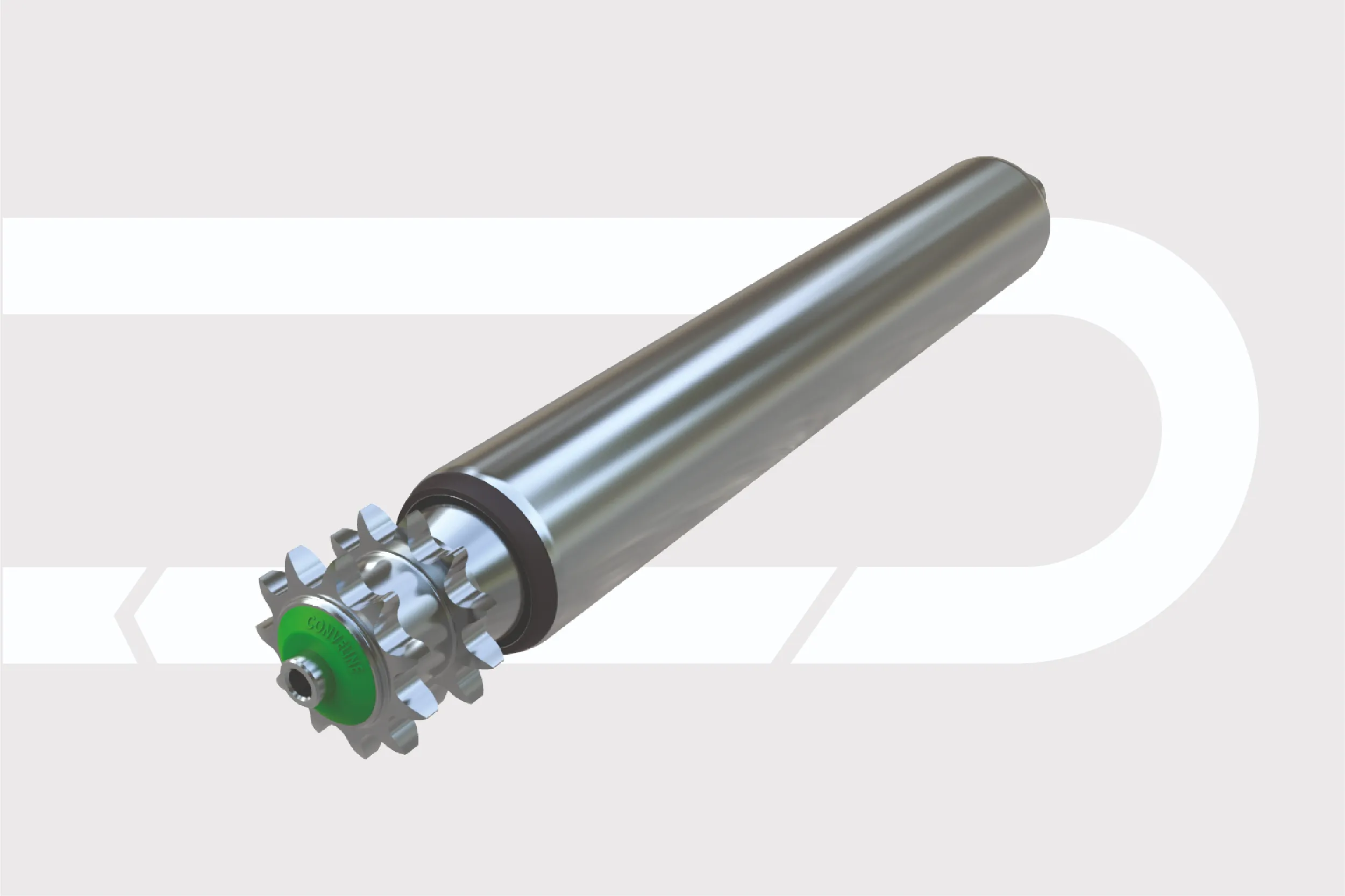

In the fast-paced realm of pharmaceuticals, precision, efficiency, and safety are paramount. Conveyor rollers have emerged as indispensable tools, revolutionizing the way pharmaceutical products are handled, manufactured, and distributed. Join us on an exciting journey through the pharmaceutical industry and discover the remarkable ways conveyor rollers contribute to its success.

- Manufacturing and Packaging

Conveyor rollers streamline the movement of raw materials, active ingredients, and packaging components within pharmaceutical manufacturing facilities. This optimized material flow ensures uninterrupted production and minimizes manual labor.

- Quality Control and Inspection

Conveyor rollers facilitate the smooth transport of pharmaceutical products through inspection stations, where quality control checks are performed. This ensures adherence to rigorous industry standards and guarantees the safety and efficacy of medicines

- Warehousing and Distribution

Conveyor rollers assist in the safe and efficient movement of biomedical waste from patient rooms and other areas to dedicated disposal areas. This ensures compliance with strict waste management protocols and maintains a hygienic environment.

- Cold Chain Management

Conveyor rollers are instrumental in maintaining the integrity of temperature-sensitive pharmaceutical products. They facilitate the movement of goods within controlled environments, preserving the required temperature conditions throughout the supply chain.

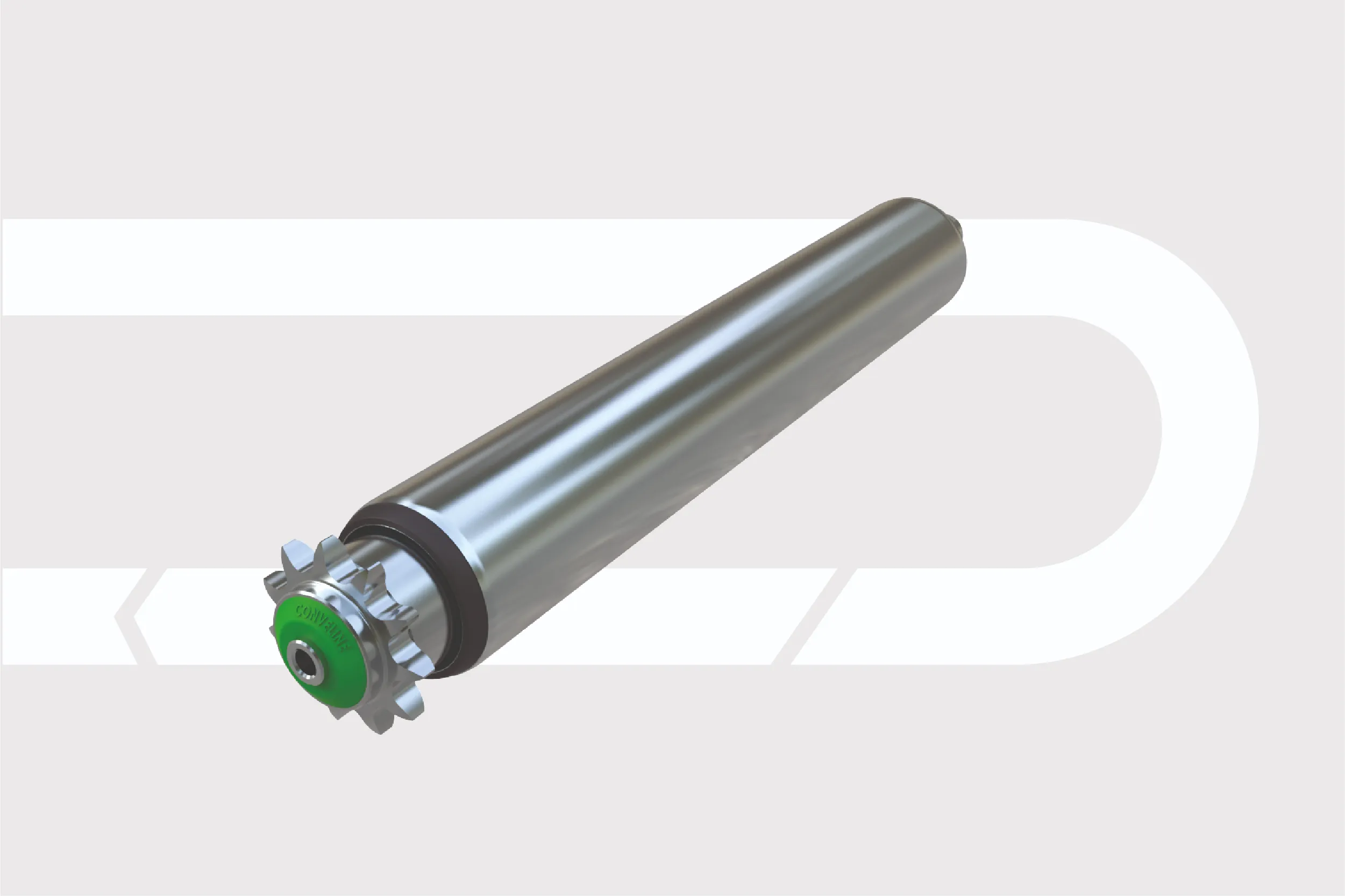

Benefits of Conveyor Rollers

So, why are conveyor rollers so important in the pharmaceutical industry? Here are just a few of the benefits that they provide:

- Enhanced Efficiency:Conveyor rollers automate material handling, reducing manual labor, and increasing operational efficiency in pharmaceutical manufacturing, packaging, and distribution processes.

- Improved Accuracy and Quality: With their precise movement and automated sorting capabilities, conveyor rollers contribute to accurate assembly, inspection, and tracking of pharmaceutical products. This ensures the delivery of high-quality medicines to patients.

- Regulatory Compliance:Conveyor rollers facilitate adherence to strict pharmaceutical regulations by ensuring accurate tracking, documentation, and quality control processes throughout the supply chain.

- Product Safety and Integrity: Conveyor rollers support the maintenance of proper storage conditions, especially in cold chain management, preserving the safety, potency, and efficacy of pharmaceutical products.