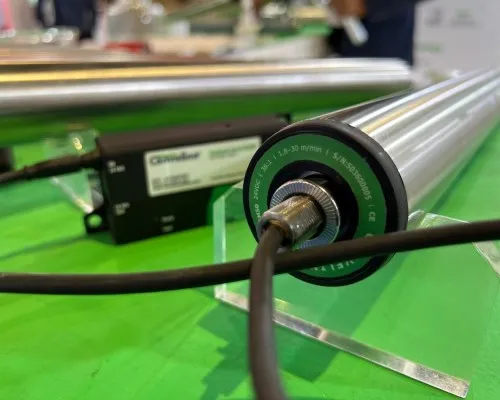

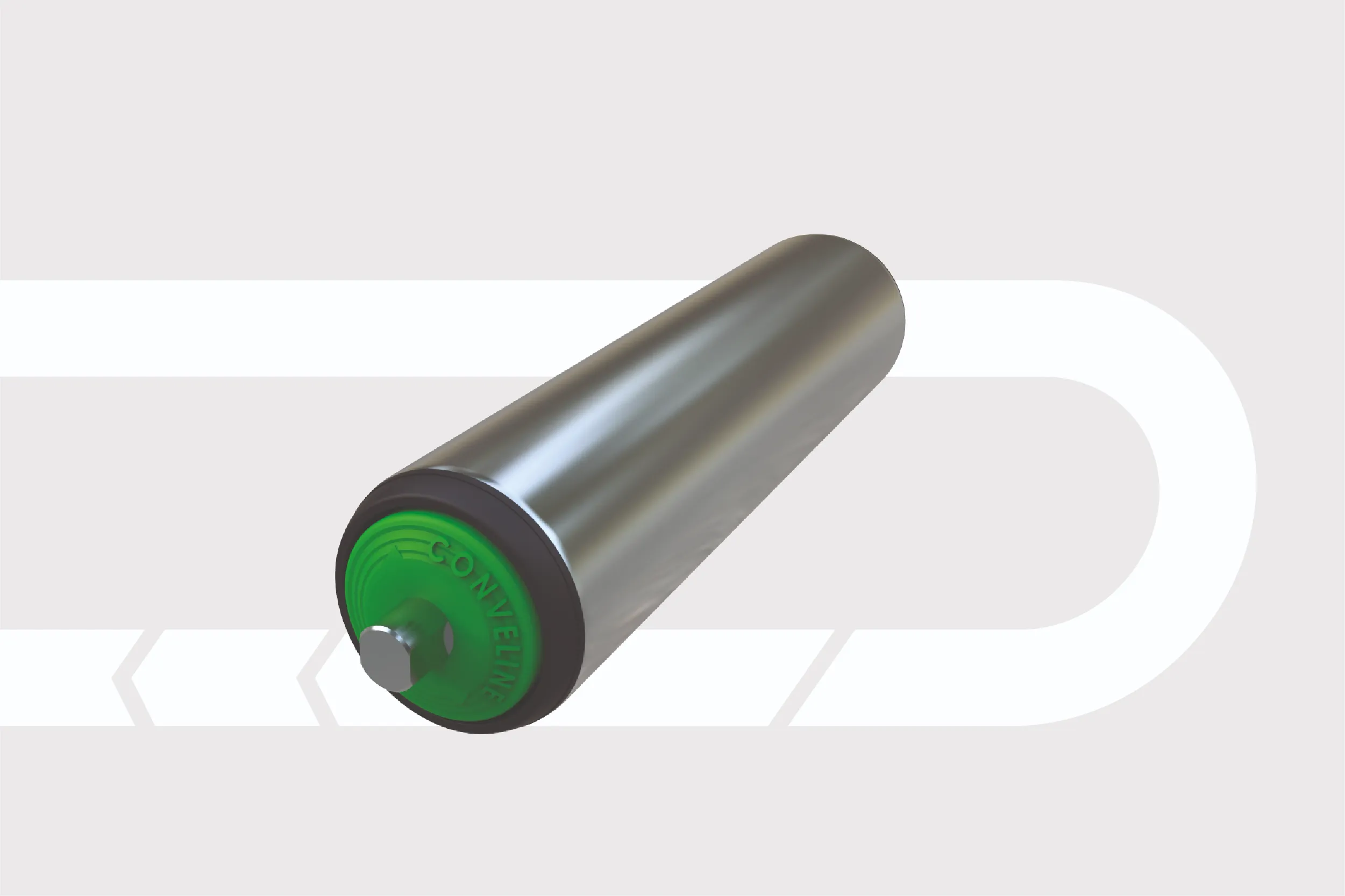

24V DC Powered Conveyor Roller

50mm 24V DC brushless motorized rollers are used in zero line pressure conveyor application. Rollers can be used supplied with additional control cards, whilst consuming less energy than others comparable powered rollers.

Benefits:

- Fast Return on Investment

- No Maintenance

- Low energy consumption

- Total cost of ownership

- Less time of installation

- Roller Motor extension cable

Technical Specification:

| Pipe Dia | 50x1.5 mm |

|---|---|

| Pipe Material | Mild Steel, Stainless Steel |

| Motor Shaft | Stainless Steel, 11mm Hex, Thread M12x1 |

| Nominal Voltage | 20-25 VDC |

| No Load Current | 0.5 A |

| Max. Continues Current | 2 A |

| Max. Start Current | 5 A |

| Mechanical Performance | 50 W |

| Noise Level | 55 DB* |

| Min. Roller Length | 270 mm (Depending on Application) |

| Max. No. of Start/Stop per Min | 30 |

| Life time under nominal condition | 20000 |

| Protection Class | IP54 |

| Ambient Temp. in Operation | 0-40℃ |

| Air Humidity | 5-85% |

| Features, Performance data and Mechanical performance apply to an ambient temp. of 20℃ | |

| *Value can change according to installation Conditions. | |

Features and Options:

- Various Drive Options

- Tapered Rollers also available

- Optional Polyurethane sleeving

- Safe low voltage

- Wide range of speeds

Load Capacity:

| Length up to 1000mm without drive pulley (Straight type) | 1100N |

|---|---|

| Length from 1100mm to 1300mm without drive pulley (Straight type) | 600N |

| Max. Load capacity per roller with drive. Pulley (poly V, O ring, Timing belt, etc.), length up to 1300mm | 350N |

Roller Motor Performance

| Gear Ratio | Speed Range(m/s) | Speed Range(m/min) | Nominal Torque(Nm) | Starting Torque(Nm) | Holding Torque(Nm) |

|---|---|---|---|---|---|

| 9:1 | 1.95 | 117 | 0.47 | 1.20 | 0.36 |

| 12:1 | 1.48 | 88.8 | 0.64 | 1.56 | 0.48 |

| 16:1 | 1.11 | 66.6 | 0.84 | 1.98 | 0.64 |

| 18.1 | 0.97 | 58.2 | 0.94 | 2.21 | 0.72 |

| 24:1 | 0.74 | 44.5 | 1.25 | 2.95 | 0.96 |

| 36:1 | 0.50 | 30 | 1.85 | 4.40 | 1.44 |

| 48:1 | 0.37 | 22.2 | 2.47 | 5.90 | 1.92 |

| 54:1 | 0.33 | 19.8 | 2.77 | 6.63 | 2.12 |

| 64:1 | 0.28 | 17.0 | 3.30 | 7.95 | 2.56 |

| 96:1 | 0.18 | 10.8 | 4.88 | 11.75 | 3.84 |

RC20 Roller Control Card

The

Conveline RC 20 Roller control is simple control for the Roller Motor RM 50 It contains no logic (e g

Zero pressure accumulation ZPA) and requires external signals for operation.

To set the direction or rotation, start and breaking ramp and the speed in 15 increments, DIP switches

can be great used Digital Inputs and outputs serves as interface to a higher level control Signals allow

adjusting the direction of rotation and speed in seven different increments

Application Area:

- Control of roller motor RM 50 in applications without start stop operation

- Application with PLC but without fieldbus

Technical Specification:

| Rated Voltage | 24V DC |

|---|---|

| Voltage Range | 20-25V DC |

| Fuse | Present, Non-Replacable |

| Protection Classification | IP20 |

| Ambient temperature in operation | 0-45℃ |

| Power Supply | Fine-wired, 1.5mm2 |

| Input/Output (I/O) | Fine-wired, 0.08 - 0.5mm2 |

Features and Options:

- Speed setting (DIP switches 15x, Digital input 7x)

- Selection of direction of rotation (via. DIP switches or digital input)

- Error signal output

- Status display with LED

Why Choose Conveline

manufacturing Area

Manufacturing Capacity Yearly

Manufactured in India

manufacturer of Conveyor Rollers

Roller Range :

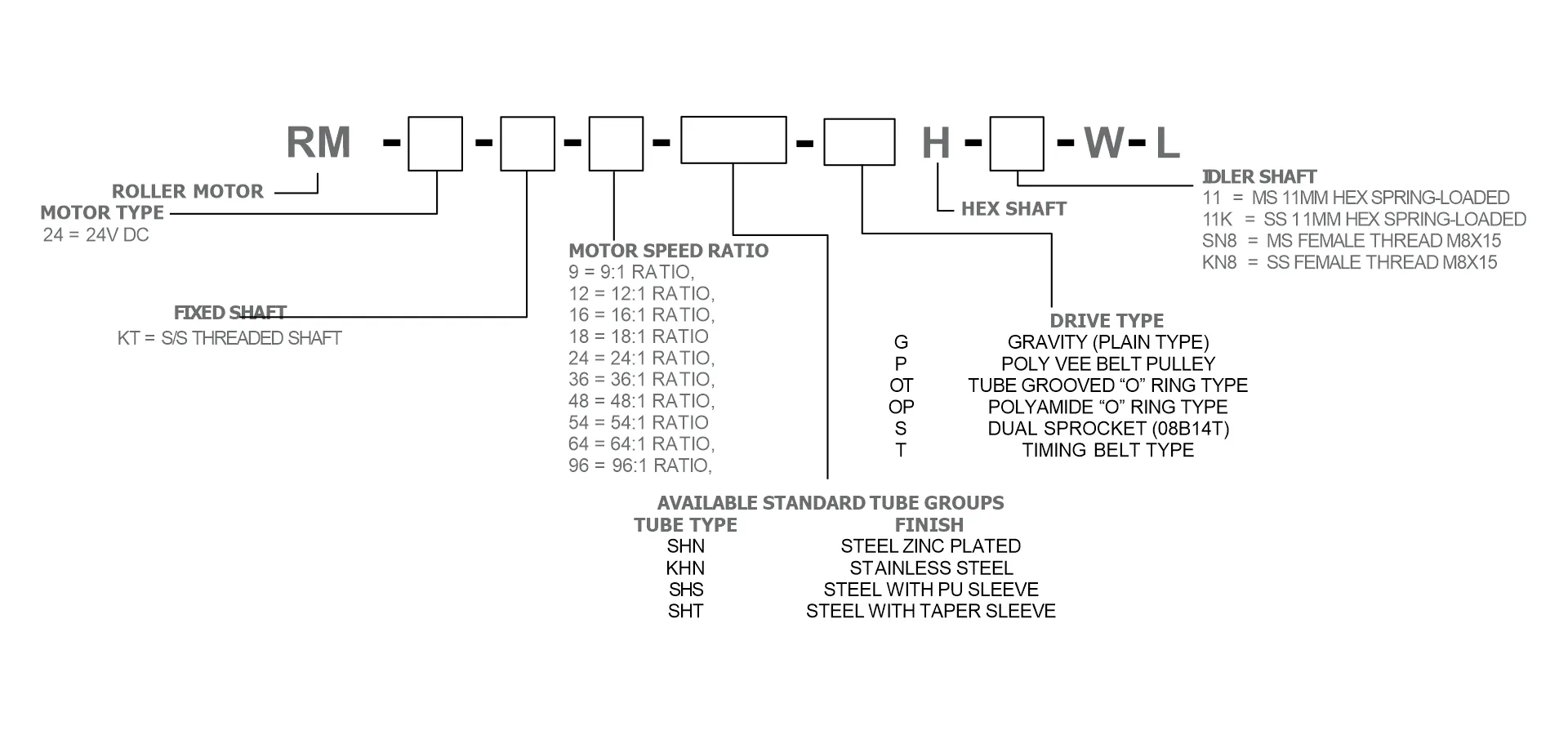

How To Order 24V DC Power Rollers

How To Order 24V DC Power Rollers

Please create a reference number with the following configurator.

Usage of 24V DC Power Rollers

Usage of 24V DC Power Rollers

24V DC powered rollers are a popular choice for many industrial conveyor systems. They are widely used in assembly lines, distribution centers, warehouses, and other material handling applications. The rollers are powered by a 24V DC motor, which provides a safe and efficient way to transport goods from one point to another.

Here are some of the common usages of 24V DC powered rollers:

- Conveyor systems: 24V DC powered rollers are commonly used in conveyor systems to transport goods. They can be used in straight or curved sections of the conveyor and can handle a variety of loads, including boxes, bags, and pallets.

- Material handling: These rollers can be used in various material handling applications, such as sorting, loading, and unloading of goods.

- Packaging: 24V DC powered rollers are also widely used in packaging applications, such as in packaging lines where they are used to transport packaged goods.

- Automotive industry: These rollers are also used in the automotive industry, where they are used in assembly lines to transport vehicle parts.

Frequently Asked Questions

Frequently Asked Questions

1. What are the benefits of using 24V DC powered rollers in conveyor systems?

- They are energy efficient

- They are safe to use

- They are easy to install

- They are low maintenance

2. Can 24V DC powered rollers handle heavy loads?

Yes, 24V DC powered rollers can handle heavy loads, depending on the size and design of the roller.

3. Are 24V DC powered rollers expensive?

The cost of 24V DC powered rollers depends on the size, design, and application. However, they are generally affordable and offer good value for money.

4. Can 24V DC powered rollers be customized?

Yes, 24V DC powered rollers can be customized to meet specific requirements, such as size, load capacity, and speed.