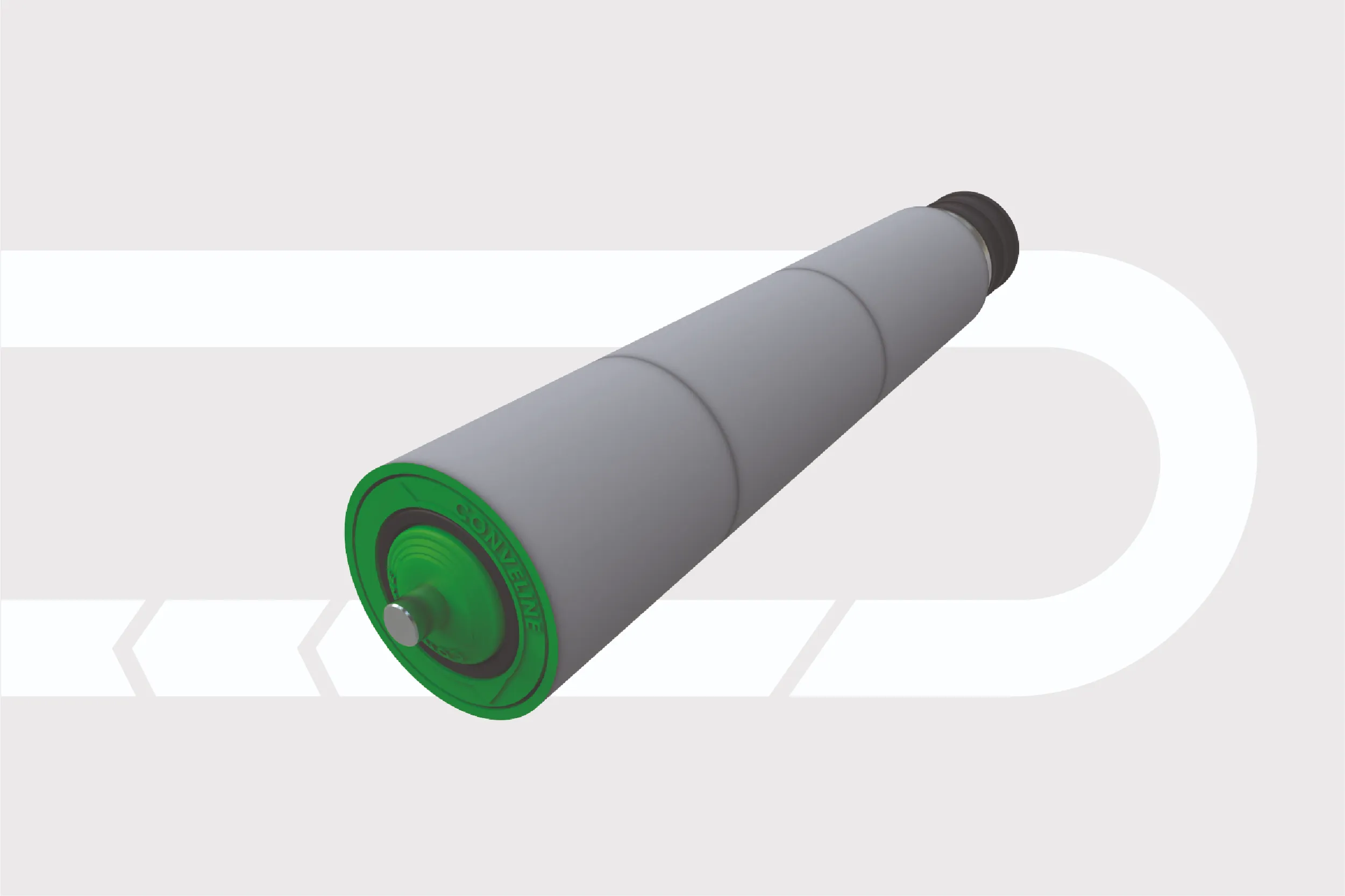

Tapered Curve Conveyor Rollers

Tapered conveyor rollers are suitable for conveyor bends and have a gray plastic tapered sleeving to ensure the correct product orientation on either powered or gravity conveyors.

Specifications:

| Series | Product Features | Diameter Range | Shaft Range |

|---|---|---|---|

| 1401 | Gravity tapered roller, attractive look and low noise | 52.9/56 | 12, 14 |

| 1402 | O belt drive, Double grooved tapered sleeve roller, customized groove position | 52.9/56 | 14 |

| 1403 | O belt pulley drive, Double grooved O belt pulley tapered sleeve roller | 52.9/56 | 14 |

| 1404 | Poly vee belt pulley drive tapered sleeve roller, high speed, low noise | 52.9/56 | 14 |

| 1405 | Polymer sprocket drive tapered sleeve roller, medium duty, low noise | 52.9/56 | 14 |

Features and Options:

- Free running option for gravity roller conveyors

- All tapered conveyor rollers have a sealed bearing option for wash-down areas

- 50mm diameter base roller can be grooved for lineshaft conveyors

- Tapered sleeve rollers to suits an inside radius of 500mm to 1200mm

- Single or double 14 teeth x 1/2” sprockets can be fitted (choice of steel or nylon sprockets)

- Mild steel and stainless steel options

- Stainless steel options available for all fixed driven conveyor rollers

Why Choose Conveline

manufacturing Area

Manufacturing Capacity Yearly

Manufactured in India

manufacturer of Conveyor Rollers

Roller Range :

Usage of Tapered Curve Rollers

Usage of Tapered Curve Rollers

Tapered curve rollers are a type of conveyor roller used in material handling systems to smoothly and efficiently transport products and materials around corners or curves. Here are some of the usages of tapered curve rollers:

- Curve Conveying: Tapered curve rollers are primarily used for conveying products and materials around curved sections of a conveyor system. They allow for a smooth transition between straight and curved sections and help to prevent products from getting stuck or jammed.

- Sorting and Merging: Tapered curve rollers can also be used in sorting and merging applications, where products or materials need to be directed to specific lanes or merged into a single lane. They can be used in combination with other types of rollers and sensors to create an efficient and reliable sorting system.

- Gravity Conveyor Systems: Tapered curve rollers can be used in gravity conveyor systems, where products or materials are moved along a conveyor by gravity. The tapered design of the rollers helps to keep products centered and prevents them from slipping or tipping over as they move around curves.

- Accumulation: Tapered curve rollers can also be used in accumulation systems, where products or materials are temporarily stopped or held in place before being released onto the next section of the conveyor. The tapered design of the rollers helps to prevent product damage and allows for smooth and consistent release of products.

Frequently Asked Questions

Frequently Asked Questions

1. What are the common materials used to manufacture tapered curve rollers?

Tapered curve rollers are usually made of high-quality steel, aluminum, or plastic materials.

2. What is the weight capacity of tapered curve rollers?

The weight capacity of tapered curve rollers may vary depending on the material and size of the rollers. However, they are usually designed to carry light to medium loads.

3. How are tapered curve rollers installed?

Tapered curve rollers can be easily installed in a conveyor system by mounting them onto the conveyor frame using bolts or screws. They can be installed at a variety of angles to create a curve in the conveyor system.

4. What are the benefits of using tapered curve rollers in a conveyor system?

Tapered curve rollers provide a smooth transition for products as they move around a curve in the conveyor system. They also help to reduce product damage, increase efficiency, and minimize the risk of jams or blockages in the system.

How To Import Tapered Curve Rollerss

How To Import Tapered Curve Rollerss

Conveline Systems Pvt. Ltd is a leading manufacturer and supplier of high-quality Tapered Curve Rollerss in India. If you're interested in importing Tapered Curve Rollerss from Conveline Systems Pvt. Ltd, here are some steps you can follow:

- Contact Conveline Systems Pvt. Ltd: The first step to import Tapered Curve Rollerss from Conveline Systems Pvt. Ltd is to get in touch with them. You can either call them or send an email to their sales team. They will provide you with all the necessary information regarding their products and the importing process.

- Discuss your requirements: Once you have contacted Conveline Systems Pvt. Ltd, you should discuss your requirements with their sales team. They will help you choose the right type of Tapered Curve Rollerss based on your specific needs.

- Get a quotation: After discussing your requirements with Conveline Systems Pvt. Ltd, they will provide you with a quotation. This will include the price of the Tapered Curve Rollerss, shipping costs, and any other applicable fees.

- Place your order: If you're satisfied with the quotation provided by Conveline Systems Pvt. Ltd, you can place your order. They will then prepare your order and arrange for it to be shipped to your desired location.

- Receive your order: Once your order has been shipped, you will receive it at your desired location. Conveline Systems Pvt. Ltd ensures that their products are packaged safely to avoid any damage during transportation.

It is important to note that importing Tapered Curve Rollerss from Conveline Systems Pvt. Ltd may require compliance with certain import regulations and customs clearance procedures. It is recommended to seek the advice of a customs broker or freight forwarder to ensure a smooth importing process.