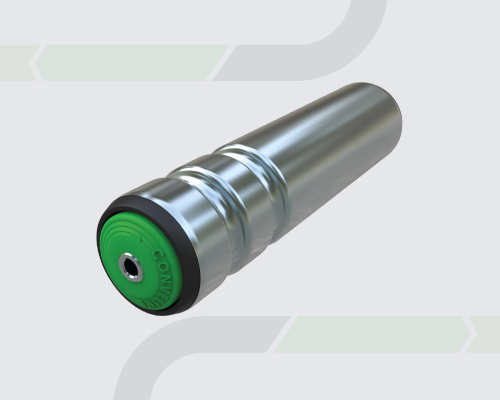

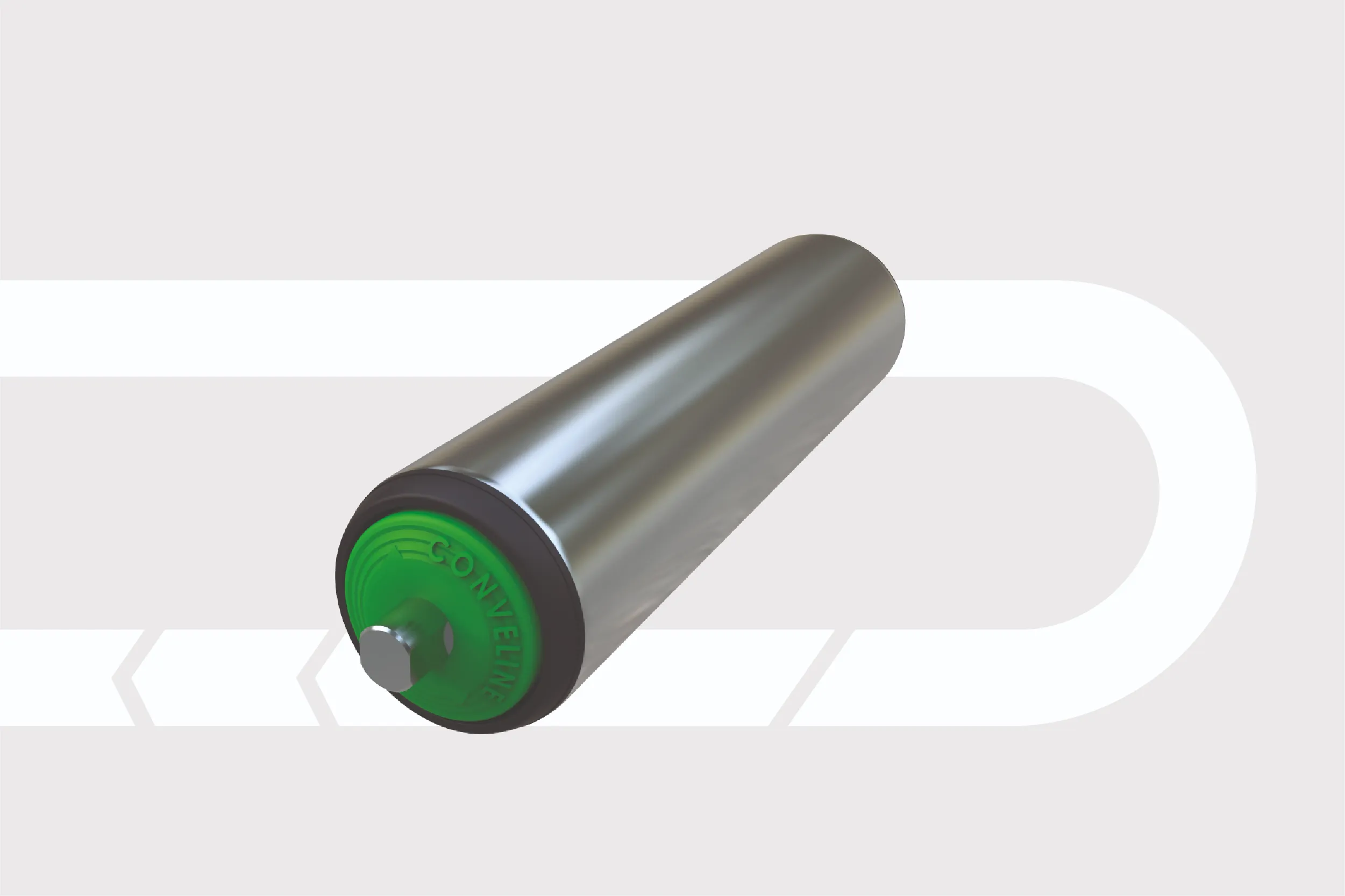

Motorized Conveyor Rollers Conveyor Manufacturer

Conveline Rollers is a well-known name as a leading Motorized Conveyor Rollers conveyor manufacturer in India, offering high-performance conveyor solutions that enhance efficiency across various industries. Our MDR conveyors are designed with advanced technology to ensure smart, energy-efficient, and safe material handling. These systems use motorized drive rollers that operate on low-voltage 24V DC motors, making them ideal for modern production and distribution facilities. Unlike traditional conveyors, MDR systems eliminate the need for external drive motors, chains, or belts, offering a cleaner, quieter, and more reliable alternative.

Each motorized drive roller conveyor segment operates independently, allowing for precise control over product movement, accumulation, and sorting. Conveline Rollers provides MDR conveyors in various finishes, such as stainless steel, PVC, and urethane-coated rollers, making them suitable for diverse applications, including food-grade environments and industrial uses. With options to customize length, speed, and zone configurations, our MDR conveyors are perfect for industries like e-commerce, automotive, pharmaceutical, and logistics. The flexible design enables integration with existing systems and supports plug-and-play functionality, reducing installation and operational downtime. As a premier Motorized Conveyor Rollers conveyor manufacturer, Conveline Rollers provides reliable, long-lasting systems that adapt seamlessly to your evolving business needs.

How MDR (Motorized Drive Roller) Conveyors Work?

MDR (Motorized Drive Roller) conveyors operate on a decentralized drive system where each conveyor zone is powered by an individual motorized roller. These rollers are internally powered by a 24V DC brushless motor. Connected to a series of idler rollers via poly-V or round belts, the motorized roller transfers motion to the other rollers in that specific section or “zone.” This enables each zone to move independently, creating a dynamic, zero-pressure accumulation system.

The system is controlled by logic-driven control cards, typically using Ethernet or I/O networks. These cards communicate with sensors placed along the conveyor line to detect the presence or absence of products. When a product is detected in a zone, the sensor signals the motor to stop that zone, allowing the product to accumulate without contact with others. This “Run-on-Demand” mechanism ensures that only the zones actively moving products are powered, saving energy and extending the system’s lifespan. MDR conveyors can be programmed to divert, merge, or sort items based on customized logic. With scalable programming and modular design, these conveyors provide seamless movement with high control over speed, direction, flow, and efficient material handling solutions for any facility.

Technical Specification:

| Pipe Dia | 50x1.5 mm |

|---|---|

| Pipe Material | Mild Steel, Stainless Steel |

| Motor Shaft | Stainless Steel, 11mm Hex, Thread M12x1 |

| Nominal Voltage | 20-25 VDC |

| No Load Current | 0.5 A |

| Max. Continues Current | 2 A |

| Max. Start Current | 5 A |

| Mechanical Performance | 50 W |

| Noise Level | 55 DB* |

| Min. Roller Length | 270 mm (Depending on Application) |

| Max. No. of Start/Stop per Min | 30 |

| Life time under nominal condition | 20000 |

| Protection Class | IP54 |

| Ambient Temp. in Operation | 0-40℃ |

| Air Humidity | 5-85% |

| Features, Performance data and Mechanical performance apply to an ambient temp. of 20℃ | |

| *Value can change according to installation Conditions. | |

Benefits:

- Fast Return on Investment

- No Maintenance

- Low energy consumption

- Total cost of ownership

- Less time of installation

- Roller Motor extension cable

Load Capacity:

| Length up to 1000mm without drive pulley (Straight type) | 1100N |

|---|---|

| Length from 1100mm to 1300mm without drive pulley (Straight type) | 600N |

| Max. Load capacity per roller with drive. Pulley (poly V, O ring, Timing belt, etc.), length up to 1300mm | 350N |

Features & Benefits of Motorized Conveyor Rollers Conveyor

- Energy Efficiency: Conveline Rollers’ Motorized Conveyor Rollers conveyors operate only when needed, significantly reducing power usage and lowering overall energy costs compared to conventional systems.

- Modular and Flexible Design: These conveyors are built with a modular structure, allowing businesses to easily modify or expand the system as per evolving production layouts or workflow requirements.

- Precise and Controlled Movement: Each MDR can be powered independently, offering excellent control for accurate product positioning, merging, diverting, or accumulating without manual interference.

- Reduced Maintenance: With minimal moving parts, the MDR conveyor system experiences less wear and tear, resulting in fewer breakdowns and reduced maintenance efforts over time.

- Quiet and Safe Operation: The decentralized motors ensure smooth and noise-free performance, creating a safer and more comfortable workspace while reducing the risk of operational accidents.

- Plug-and-Play Integration: Conveline Rollers’ MDR Conveyors come equipped with standard interfaces that simplify the installation process and allow for seamless integration with existing conveyor setups.

- Scalability: As operations expand, MDR Conveyors can be quickly scaled up or reconfigured to meet higher load capacities or complex material handling requirements without overhauling the entire system.

- Fault Detection and Diagnostics: Select MDR models are equipped with smart sensors and monitoring tools, allowing real-time diagnostics, early issue detection, and ensuring system reliability at all times.

Usage of Motorized Conveyor Rollers Conveyor

Conveline Rollers' Motorized Conveyor Rollers conveyors are a perfect choice for modern material handling. These conveyors run on 24V DC motors, making them energy-efficient, safe, and ideal for moving goods across different zones with ease. Their compact design and intelligent functionality make them suitable for a wide range of industries and operations.

Here are some of the key applications of MDR conveyors:

- Conveyor Systems: MDR (motorized drive rollers) are widely used in conveyor lines to move cartons, totes, or pallets. They are perfect for both straight and curved sections, handling lightweight to medium loads effectively.

- Material Handling: These rollers are commonly used for applications like sorting, accumulation, merging, and transferring items across different points of a facility.

- Automotive Industry: In automotive assembly lines, MDR conveyors help in transporting vehicle parts between workstations, providing smooth and uninterrupted production flow.

- E-commerce and Fulfillment Centers: Conveline’s MDR systems are highly effective in processing high-volume parcels, ensuring quick movement from inbound to outbound docks.

- Distribution and Warehousing: These Motorized Conveyor Rollers conveyors boost operational efficiency by streamlining goods flow, reducing manual handling, and enhancing inventory accuracy.

- Manufacturing and Assembly Lines: Motorized Conveyor Rollers conveyors support the continuous movement of components, helping manufacturers increase throughput and maintain consistent production.

- Postal and Package Sorting: MDR conveyors are perfect for logistics hubs and postal services, where they aid in fast, automated sorting and routing of parcels based on size or destination.

Why Choose Conveline

manufacturing Area

Manufacturing Capacity Yearly

Manufactured in India

manufacturer of Conveyor Rollers

Roller Range :

Frequently Asked Questions

Frequently Asked Questions

1. What is a Motorized Conveyor Rollers Conveyor?

An MDR Conveyor uses 24V DC-powered rollers to move products efficiently and safely along a conveyor system. It enables zone-based accumulation, sorting, and transferring of items without the need for pneumatics.

2. Where are MDR Conveyors commonly used?

MDR Conveyors are used in warehouses, distribution centers, e-commerce facilities, manufacturing units, postal services, and automotive assembly lines.

3. What are the advantages of using MDR Conveyors over traditional conveyors?

Motorized drive roller conveyors are energy-efficient, low-noise, safe, modular, and require less maintenance due to fewer moving parts.

4. Can MDR conveyor systems handle heavy loads?

Yes, Conveline Rollers' MDR conveyor systems are designed to handle a wide range of load capacities, from light packages to heavier boxes and totes.

5. Are MDR Conveyors easy to integrate with existing systems?

Yes, MDR conveyors feature plug-and-play components and standard interfaces, allowing for easy integration into existing layouts.

6. How energy-efficient are MDR Conveyors?

They use "run-on-demand" technology, meaning rollers operate only when required—saving energy during idle times.

7. Can MDR Conveyors be customized?

Absolutely. Conveline Rollers offers customizable MDR solutions to meet specific layouts, capacity, and functional needs.

8. How do MDR Conveyors improve workplace safety?

The low-voltage motorized rollers reduce the risk of injury and create a quieter, more comfortable working environment.

9. What kind of maintenance is required for MDR Conveyors?

Minimal maintenance is needed as they have fewer moving parts and are designed for long-term, reliable operation.

10. Do MDR Conveyors support smart features like fault detection?

Yes, advanced models include sensors and software for real-time monitoring, diagnostics, and fault alerts.

We Export MDR Worldwide

We Export MDR Worldwide

Russia | USA | UAE | Australia | Malaysia | France | Kuwait | Saudi Arabia | Singapore | Switzerland | Qatar | South Korea | Bangladesh | Czech Republic | The Netherlands | Kazakhstan | Nigeria | Vietnam | Oman | Thailand | Mexico | Argentina | Brazil | Canada | India | Japan | Indonesia | New Zealand | Egypt | South Africa | Philippines | Turkey | Greece | Norway | Sweden | Portugal | Spain | Italy | Belgium | Poland | Ireland | Austria | Denmark | Finland | Israel | Iran | Iraq | Lebanon | Jordan | Syria | Libya | Algeria | Morocco | Sudan | Kenya | Uganda | Zimbabwe | Angola | Cambodia | Nepal | Sri Lanka | Myanmar | Afghanistan | Ethiopia | Ghana | Peru | Chile | Bolivia | Honduras | Guatemala | Ecuador | Paraguay | Uruguay | Serbia | Croatia | Bosnia and Herzegovina | Iceland | Luxembourg | Belarus | Ukraine | Lithuania | Latvia | Estonia | Georgia | Armenia | Azerbaijan | Yemen | Bahrain | Cyprus | Maldives | Brunei | Bhutan | Laos | Mauritius | Seychelles | Barbados | Jamaica | Trinidad and Tobago | Fiji | Solomon Islands | Micronesia | Vanuatu | Malta | Albania | Moldova | Slovenia | Macedonia | Montenegro | Kosovo | Suriname | Guyana | Belize | Nicaragua | El Salvador | Panama | Costa Rica | The Bahamas | Eswatini | Botswana | Namibia | Lesotho | Zambia | Malawi | Rwanda | Burundi | Djibouti | Eritrea | Somalia | Chad | Republic of the Congo | Democratic Republic of the Congo | Gabon | Equatorial Guinea | Guinea | Guinea-Bissau | The Gambia | Liberia | Sierra Leone | Togo | Benin | Burkina Faso | Ivory Coast | Senegal | Mali | Niger | Mauritania | Mozambique | Madagascar | Turkmenistan | Uzbekistan | Tajikistan | Kyrgyzstan | Palestine | East Timor | China | Pakistan | Hungary | Romania | Bulgaria | Slovakia | Venezuela | Colombia